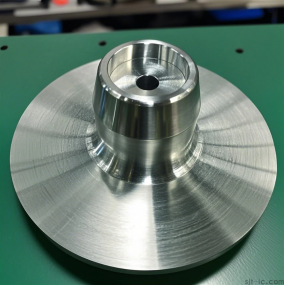

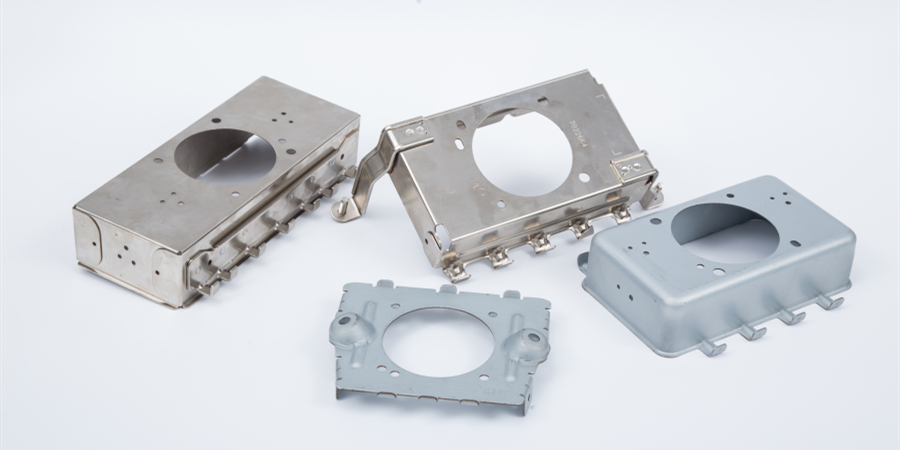

The process of producing automotive parts in general Metal Stamping processing plants is: stamping - cleaning - welding - degreasing - cleaning - electrophoresis, etc.

1. When designing the structural shape of automotive parts, it is best for metal stamping factories to adopt a simple and reasonable structure, and to minimize the number of machined surfaces and the machining area as much as possible;

2. The materials used in automotive hardware stamping parts not only meet the technical requirements of product design, but also the stamping process requirements in the stamping processing plant, as well as the processing requirements of cutting, electroplating, cleaning and other processes after stamping;

3. The requirements for the forming performance of automotive stamping in metal stamping parts processing plants. Regarding the forming process, in order to facilitate stamping deformation and improve the quality of the parts, the material should have good plasticity, a large directional coefficient of plate thickness, a small directional coefficient of plate plane, and a small ratio of yield strength to elastic modulus of the material. Regarding the separation process, it is not necessary for the material to have good plasticity, but it should have a certain degree of plasticity. The better the plasticity of the material, the less likely it is to separate.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque