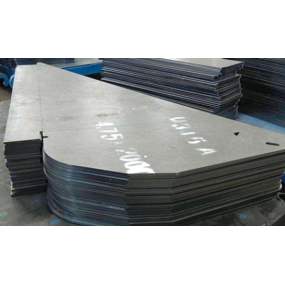

Deep drawing is a common forming method in Metal Stamping processing. However, there are often some difficulties encountered during the deep drawing process, one of which is how to choose the appropriate mold fillet radius.

The fillet radius of the mold has a significant impact on deep drawing forming. If the fillet radius is too small, it can cause scratches, dents, and other problems on the surface of the workpiece; If the fillet radius is too large, it will cause distortion and deformation of the workpiece. Therefore, choosing the appropriate mold fillet radius is crucial.

So, how to choose the appropriate mold fillet radius? Generally speaking, the following factors need to be considered:

1. Material properties: Different materials have different plasticity and ductility. Therefore, when selecting the appropriate mold fillet radius, it is necessary to adjust it according to the properties of the material.

2. Workpiece shape: Workpiece shape also affects the selection of mold fillet radius. For example, for workpieces with complex shapes, it may be necessary to choose smaller fillet radii; For workpieces with simple shapes, larger fillet radii can be chosen.

3. Deep drawing depth: The depth of deep drawing also affects the selection of the fillet radius of the mold. Generally speaking, as the depth of deep drawing increases, the required fillet radius of the mold will also increase accordingly.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque