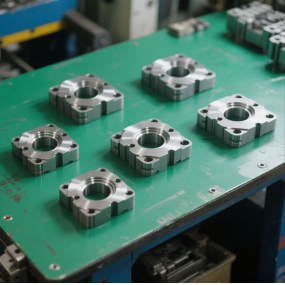

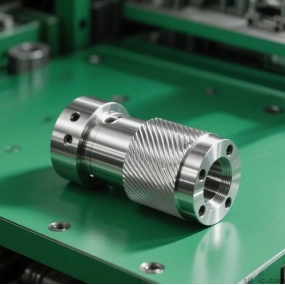

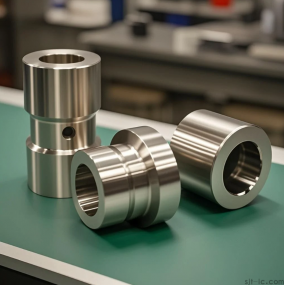

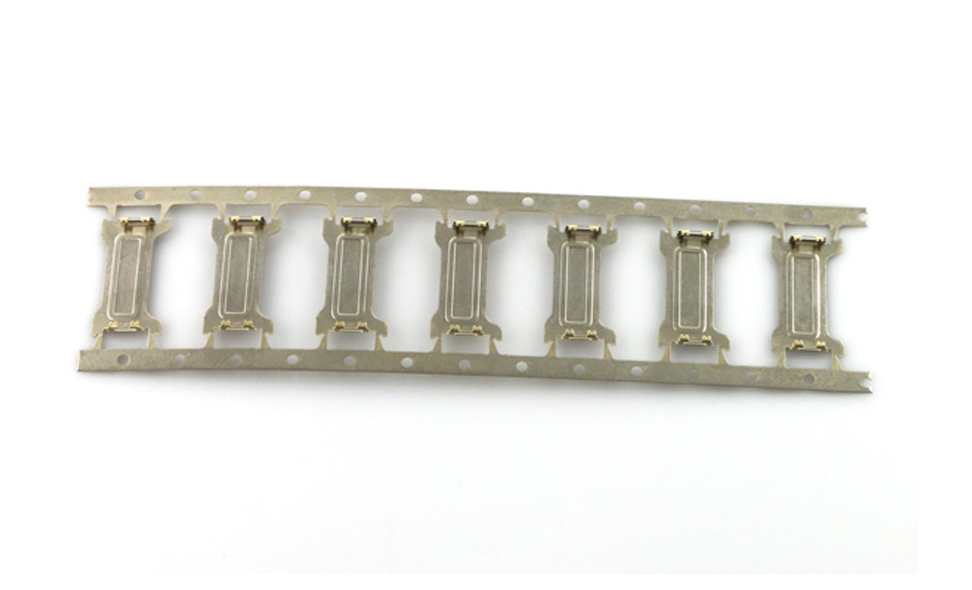

Metal Stamping processing is an indispensable part of modern manufacturing, involving numerous details and techniques. This article will analyze the details of metal stamping processing, from process review to preventing scratches.

In the process of metal stamping, process review is a very important step. It can help us ensure the quality of our products and avoid unnecessary problems. Process review includes a detailed inspection of molds, equipment, materials, etc. to ensure they meet production requirements.

In addition, during the metal stamping process, we also need to pay attention to preventing scratches. Scratches can cause unsightly appearance of the product and affect its sales. To prevent scratches, we can take some measures, such as using high-quality molds and equipment, and regularly maintaining and servicing the molds and equipment.

Metal stamping processing is a complex task that involves numerous techniques and details. Only through strict process review and effective protective measures can we produce high-quality products.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque