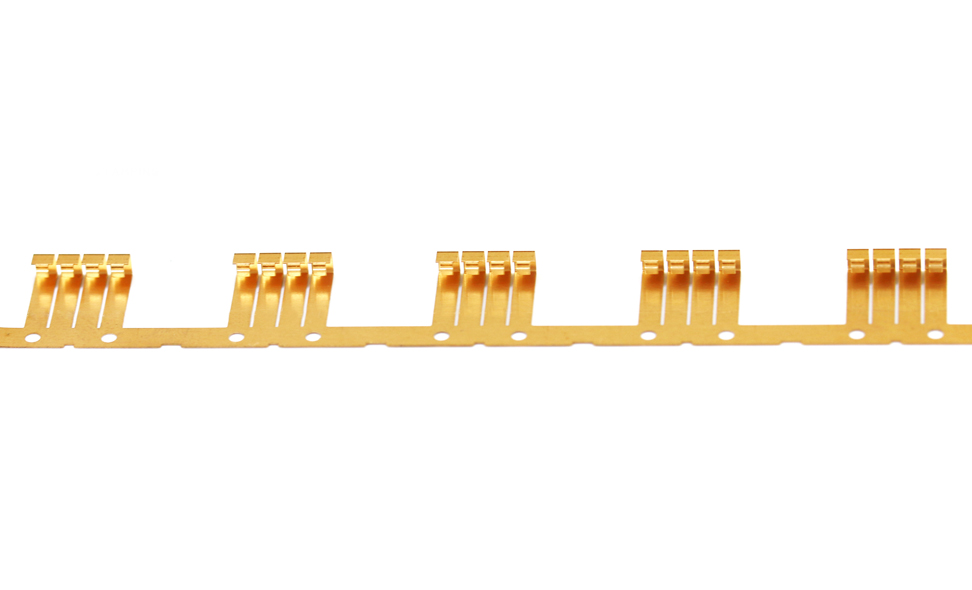

In Metal Stamping processing, punching technology is an important process. It can effectively improve production efficiency and product quality. But how to ensure the quality and dimensional accuracy requirements of the parts?

Firstly, we need to perform precise calculations for the cutting process. This includes determining factors such as mold clearance, blade sharpness, and material thickness. Only by accurately calculating these factors can the quality and dimensional accuracy requirements of the parts be guaranteed.

Secondly, we also need to choose suitable stamping equipment and molds. Different equipment and molds have different characteristics and applicable ranges. Therefore, when making a choice, we need to consider comprehensively based on actual production needs.

Finally, we also need to pay attention to the operational standards during the production process. This includes skills training for operators, equipment maintenance and upkeep, and other aspects. Only by doing these tasks well can we ensure the stability of the production process and product quality.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque