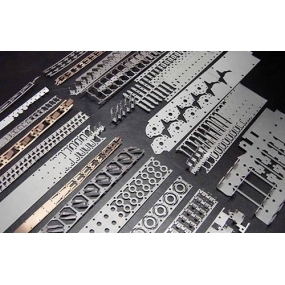

Precision machining technology is a high-precision machining method that can achieve high-precision machining of parts through precision mechanical equipment and advanced machining processes. To ensure the accuracy of parts, it is usually necessary to control and guarantee from the following aspects:

1、 Material selection

It is very important to choose high-quality materials suitable for machining parts during precision machining. For parts that require high precision, it is necessary to choose materials with uniform density, high hardness, low thermal expansion coefficient, and good stability. Only by selecting suitable materials can the stability and accuracy of the parts be guaranteed.

2、 Precision control

When performing precision machining, it is necessary to strictly control the accuracy requirements in each processing step, including workpiece positioning, clamping, tool selection, etc. During the machining process, it is necessary to select appropriate machining parameters based on the requirements of the parts and the process, such as cutting speed, feed rate, cutting depth, etc., to ensure the accuracy and surface quality of the parts.

3、 Equipment guarantee

Choosing precision mechanical equipment suitable for processing requirements is also an important factor in ensuring the accuracy of parts. High precision machine tools can provide a more stable machining environment, while precise control systems and sensors can ensure the machining accuracy of parts. In addition, regular maintenance and upkeep of equipment are also important means to ensure the accuracy of parts.

4、 Process optimization

Optimizing processing technology is one of the key factors in achieving high-precision machining of parts. By implementing reasonable tool path design, processing sequence arrangement, and precise finishing techniques, the accuracy and surface quality of parts can be effectively improved. During the machining process, auxiliary measures such as cutting fluid and coolant can also be used to improve machining efficiency and quality.

Overall, to ensure the accuracy of parts, comprehensive control and optimization are required in material selection, precision control, equipment assurance, and process optimization. Only by ensuring the stability and accuracy of each link can the requirements for high-precision machining of parts be achieved. Precision machining technology has played an important role in this regard, and by continuously improving the level of technology and process methods, it can better meet the market's demand for high-precision parts.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque