Metal processing refers to the process of transforming metal raw materials into various metal products through a series of technological processes. Common metal product processing techniques include:

Sawing: Cutting metal raw materials into the desired size and shape. Common tools include band saws, hand saws, etc.

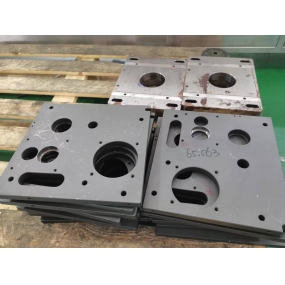

Drilling: Drilling holes on metal surfaces with a drill bit to create connection holes or through holes for metal products.

Punching and cutting: Using a punch press or stamping machine to punch metal sheets into the desired shape of parts.

Bending: Using a bending machine to bend metal sheets into the desired curvature or angle.

Welding: Connecting metal components using welding methods, common welding methods include arc welding, gas shielded welding, etc.

Precision machining: Precision machining of metals through mechanical equipment such as lathes and milling machines, including turning, milling, and other processes.

Surface treatment: Spraying, chrome plating, sandblasting and other treatments are applied to the surface of metal products to increase their glossiness and corrosion resistance.

Assembly: Assemble various metal components according to design requirements to form finished metal products.

Inspection: Conduct quality inspection on finished metal products to ensure that they meet design requirements and standards.

The above are common process flows for metal product processing, and each link requires precise operation and strict quality control to ensure the quality and performance of the products.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque