1. Machine stability: Five axis CNC machine tools require high stability to ensure accuracy and repeatability during the machining process. The structure of the machine tool should be reinforced and equipped with effective anti vibration measures.

2. Control system: Five axis CNC machine tools require an excellent control system that can monitor and control the motion of multiple axes in real time. The control system should have high-precision orientation control and interpolation functions to complete messy processing paths.

3. Tool selection: Five axis CNC Machining generally requires the use of longer tools to reach deeper machining areas. The selection of cutting tools should take into account rigidity, cutting performance, and wear resistance to ensure machining quality and power.

4. Processing strategy: Five axis CNC machining can achieve more processing directions and angles, so a more chaotic processing strategy can be adopted. A reasonable machining strategy can reduce machining time, improve surface quality, and reduce tool wear.

5. Programming: Five axis CNC machining requires writing messy machining programs to complete messy machining paths and cutting conditions. The programming requirements fully understand the various shapes and process requirements of the machining policy, and consider the optimization and safety of the tool path together.

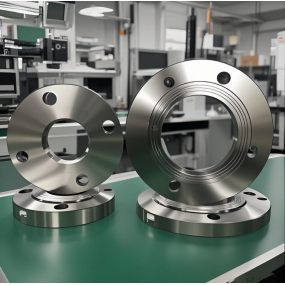

6. Preparation before machining: Adequate preparation work is required before performing five axis CNC precision machining. This includes selecting appropriate fixtures and workpiece fixing methods, confirming reasonable cutting tools and processing parameters, and conducting necessary process tests and calibrations.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque