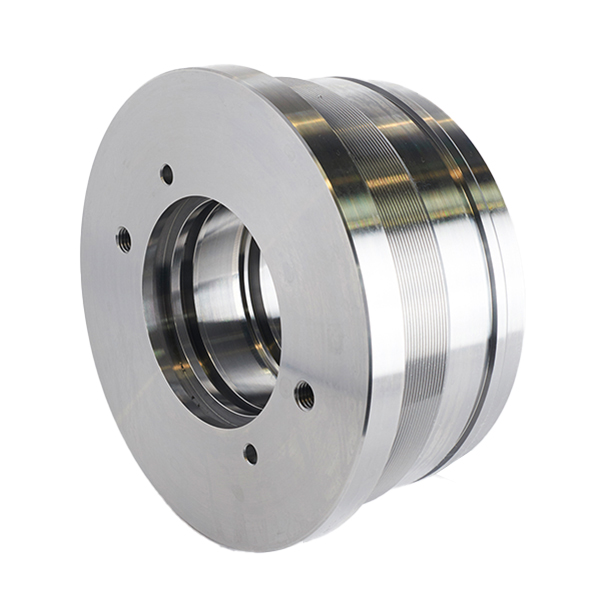

Precision hardware parts processing is a process involving high precision and strict tolerance requirements, widely used in multiple industries such as electronics, machinery, aviation, and new energy. Precision hardware parts processing requires a series of high-precision and high-efficiency equipment to ensure processing quality and production efficiency. The following are some commonly used equipment: 1. CNC machine tool CNC lathe: It completes machining by controlling the relative motion of the tool and workpiece through computer programs, and has the characteristics of high precision, high efficiency, and high reliability. Numerical control lathes are mainly used for machining various rotating surfaces and end faces of rotating bodies, such as turning inner and outer cylindrical surfaces, conical surfaces, ring grooves, and forming rotary surfaces. CNC Machining center: It can perform high-precision and high-efficiency machining on complex workpieces, with multi axis linkage capability, and can machine various shapes such as curved surfaces, cavities, convex and concave surfaces. Numerical control machining centers play an important role in the processing of precision hardware parts, capable of completing various complex shaped machining tasks.  II. Precision Tool Grinding Machine: Used for grinding precision parts, it can achieve very high precision and surface quality. Grinding processing can effectively remove burrs and unevenness on the surface of workpieces, and is one of the important means of precision machining. Internal and external cylindrical grinding machine: specifically used for precision grinding of internal and external cylindrical surfaces, ensuring the dimensional accuracy and surface quality of parts. 3、 Electrical Discharge Machining (EDM) Machine: Precision machining is performed through the discharge of electrical pulses between electrodes and workpieces. During electrical discharge machining, it can ensure that the surface of the workpiece is very smooth and free of burrs, resulting in better accuracy and surface quality of the workpiece. Wire cutting machine: commonly used for processing metal materials with relatively high hardness. Wire cutting machines can cut metal materials into various shapes, and their accuracy and cutting surface quality are far higher than traditional cutting processes. In the production of precision hardware accessories, wire cutting machines are a good choice. 4、 Other equipment shearing machine: a machine equipment used for cutting metal materials, which can cut various sizes and shapes of metal materials through locators and cutting edges. Welding equipment: Two metal parts can be welded together at high temperature through various forms such as arc welding, gas welding, laser welding, etc. Welding equipment is used in hardware processing to produce various welding components. Punch press: a machine equipment that processes various hardware components through stamping actions on molds, and can perform multiple continuous stamping actions. Punching machines are widely used in the processing of hardware parts. Screw machine: Tighten or loosen screws in a faster and more accurate manner, improving production efficiency and ensuring product quality. Cutting machine: The main equipment used for cutting metal materials, capable of cutting metal materials into various shapes and sizes as needed. Drilling machine: a device used for drilling holes in metal materials, capable of drilling holes of various diameters and depths as needed

II. Precision Tool Grinding Machine: Used for grinding precision parts, it can achieve very high precision and surface quality. Grinding processing can effectively remove burrs and unevenness on the surface of workpieces, and is one of the important means of precision machining. Internal and external cylindrical grinding machine: specifically used for precision grinding of internal and external cylindrical surfaces, ensuring the dimensional accuracy and surface quality of parts. 3、 Electrical Discharge Machining (EDM) Machine: Precision machining is performed through the discharge of electrical pulses between electrodes and workpieces. During electrical discharge machining, it can ensure that the surface of the workpiece is very smooth and free of burrs, resulting in better accuracy and surface quality of the workpiece. Wire cutting machine: commonly used for processing metal materials with relatively high hardness. Wire cutting machines can cut metal materials into various shapes, and their accuracy and cutting surface quality are far higher than traditional cutting processes. In the production of precision hardware accessories, wire cutting machines are a good choice. 4、 Other equipment shearing machine: a machine equipment used for cutting metal materials, which can cut various sizes and shapes of metal materials through locators and cutting edges. Welding equipment: Two metal parts can be welded together at high temperature through various forms such as arc welding, gas welding, laser welding, etc. Welding equipment is used in hardware processing to produce various welding components. Punch press: a machine equipment that processes various hardware components through stamping actions on molds, and can perform multiple continuous stamping actions. Punching machines are widely used in the processing of hardware parts. Screw machine: Tighten or loosen screws in a faster and more accurate manner, improving production efficiency and ensuring product quality. Cutting machine: The main equipment used for cutting metal materials, capable of cutting metal materials into various shapes and sizes as needed. Drilling machine: a device used for drilling holes in metal materials, capable of drilling holes of various diameters and depths as needed

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque