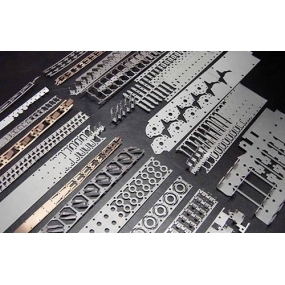

Mold grinding is a method of restoring the sharp cutting edge of the grinding tool through grinding. The quality of Metal Stamping parts should first be considered from the mold, and stamping molds have a certain production life. With the increase of stamping times, when the cutting edge wears to a certain extent, the originally sharp cutting edge will become dull, resulting in excessive burrs and decreased accuracy of stamping parts.

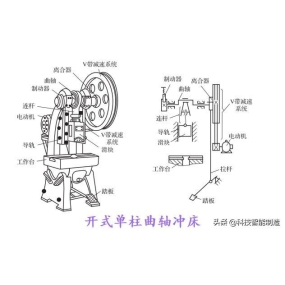

There are various methods for grinding molds, including using specialized grinding machines and completing them on surface grinders. The frequency of punch and lower die grinding is generally 4:1, please adjust the height of the mold after grinding.

Damage caused by incorrect grinding: Incorrect grinding can exacerbate the agile damage of the mold edge and affect its service life.

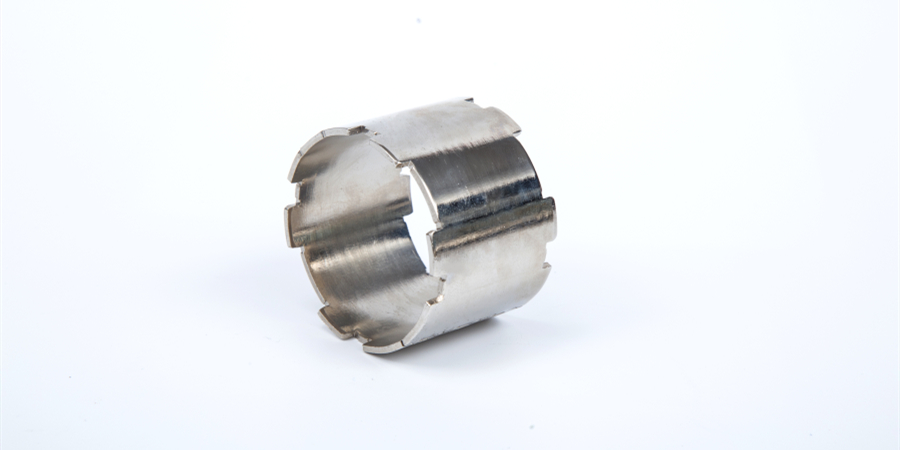

The benefits of proper sharpening: timed sharpening of molds can maintain stable quality and accuracy of punching. The blade life of the mold is longer. Precautions for Grinding the Mold: The surface of the grinding wheel should be cleaned and tidy; After grinding, it is necessary to clean, demagnetize, and lubricate the blade; Suggest using a loose, coarse-grained, soft grinding wheel. Such as WA46KV; The sharpness of the cutting edge should be considered when the rounded corner is between R0.1-0.25 millimeters; Adequate coolant must be added during grinding; The grinding amount (cutting amount) each time should not exceed 0.013 millimeters. If the grinding amount is too large, it will cause the mold surface to overheat, which is equivalent to annealing treatment, making the mold soft and greatly reducing its lifespan; After grinding, the edges should be treated with oilstone to remove excessively sharp edges; During grinding, it is necessary to ensure that the punch and lower die are fixed and stable, using specialized fixtures and jigs; The grinding amount of the mold is fixed, and if it reaches this value, the punch will be scrapped. If it continues to be used, it may cause damage to the mold and machine, resulting in small losses.

Timed grinding of molds is an important factor in ensuring the quality of metal stamping parts. If the mold is sharpened at the appropriate time, its service life can be extended by three times. However, incorrect sharpening can rapidly intensify the damage to the mold edge and reduce its service life. Therefore, mastering the correct sharpening method is very important.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque