1. Amazing accuracy, power, and cost-effectiveness

Obviously, the first point on our list is the key we mentioned earlier. The mechanic swore to this machine for a reason, even during the chaotic process. 5-axis machining is the most efficient, accurate, and improved among all similar products. Because there are fewer fixtures in multiple operations, using it directly translates to better workpiece quality and durability. This means excellent parts, less waste, lower item costs, and shorter working hours.

2. It is now possible to create cluttered shapes and viewpoints.

Traditional CNC machine tools move on three linear axes (X, Y, and Z). The 5-axis machine moves on all three linear axes and two additional rotational axes. Compared with traditional 3-axis machining, the ability to accurately move workpieces without removing them has significant advantages.

5-axis CNC machine tools can even reach cluttered viewpoints. If your parts require cluttered 4D and 5D parts, then you need a machining workshop with good 5-axis machines and skilled operators. We can combine clutter with high-quality finished products and services, which we can never achieve with a 2-axis or 3-axis machine. This is in a single setting, where everything translates into higher productivity and higher workpiece quality.

3. Able to use shorter cutting tools.

Processing shorter cutting objects can be cumbersome, especially when it comes to more versatile CNC machines. Fortunately, we are able to fully utilize better viewpoints, cutting speeds, and the strength of precision parts, as they can be installed well on 5-axis machines. Here, you can have your head facing the job and the tool facing the surface. Because the machine can grip the tool well, the load on the tool will be reduced, thereby reducing unfortunate damage and oscillation.

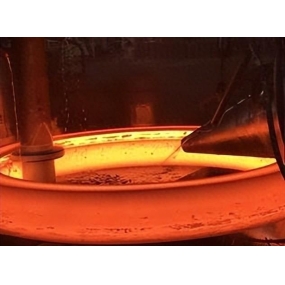

Improving drilling technology with a 4.5 axis machine tool

Using 5-axis CNC Machining and utilizing excellent drilling technology to supply excellent parts. By using our 5-axis machine, we can reach smaller and more cluttered viewpoints. This will result in a cleaner surface of the finished product. Compared to typical 3-axis machines, 5-axis machines can save time and money.

5. Better surface smoothness

By utilizing the rotating fourth and fifth axes, we are able to bring the parts closer to the tool. If the parts can be close to the tool, the tool can be shorter. Shorter cutting tools are less susceptible to oscillation at higher cutting speeds, which directly affects surface smoothness. Our 5-axis CNC machining provides a more lubricated surface than the shiny metal bottom of baby robots.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque