2.1 Maintain optimal cutting

As shown above, the left side is a 3-axis cutting mode, and when the cutting head moves towards the top or edge of the part, the cutting will gradually deteriorate. To maintain optimal cutting conditions here, you need to rotate the workbench. Moreover, to fully process irregular planes, the worktable must be rotated several times in different directions. It can be seen that by avoiding the centerline velocity of the ball cutter from becoming 0, 5-axis machining can also achieve better surface quality.

2.2 Time saving

Compared to other types of machine tools, five axis CNC machine tools will help you save a lot of time. Parts created in most CNC workshops require machining on five sides. 5-axis CNC milling will help to complete production quickly and effectively. Some simple settings are still needed, which can help save time and money.

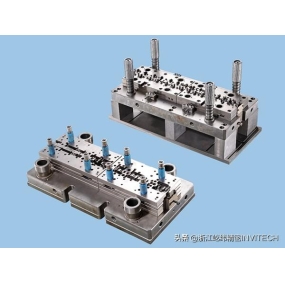

In 5-axis machining, cutting tools are used to maintain the vertical state of complex mold machining surfaces, which can greatly reduce machining time. The principle of 5-axis machining also applies to side milling with a certain angle, which can eliminate rib lines caused by ball cutters. This makes the surface quality of the mold more ideal and reduces the manual work required to clean the mold surface.

2.3 Accuracy improvement

Due to the fewer settings required for 5-axis CNC milling, it can improve accuracy. Other settings will only lead to more errors. It also helps to increase the lifespan of specific tools.

Through five axis machining technology, the problem of accurately repositioning workpieces at complex angles has been solved multiple times. It not only shortens the time, but also increases the machining tolerance multiple times. It also saves the high cost of making multiple fixtures in traditional ways. 5-axis machining can process complex parts such as drilling, taper machining, cavities for complex surfaces, etc., which in most cases cannot be achieved by traditional machining methods.

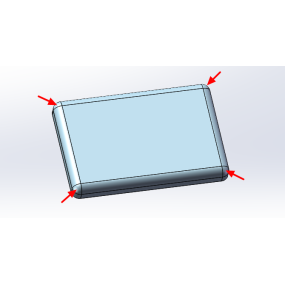

2.4 High quality surface effect

This type of configuration also helps create surfaces with high-quality smoothness. The position of the parts is closer to the cutting tools in the 5-axis machine tool. The last two axes will allow one person to use a short cutting tool that will not vibrate too much, resulting in high-quality surface finish.

Another advantage of 5-axis CNC machine tools is that they can cut complex shapes. All five axes require various parts. The additional motion in this type of arrangement provides space for creating angles and arcs. Previously, they would require additional settings and unique fixtures.

2.5 High production efficiency

Five axis machining can effectively reduce the processing time and auxiliary time of parts. It has a wide range of spindle speeds and feed ranges, giving the machine powerful cutting capabilities. Five axis machining is entering the era of high-speed machining. The rapid movement and positioning of 5-axis machining and high-speed cutting machining reduce the turnover time of semi-finished products and improve production efficiency and accuracy.

2.6 Competitive Advantage

Very few factories use 5-axis CNC machine tools. Setting up once will give you an advantage over your competitors in terms of production services. You can provide customers with services that competitors cannot offer. You should try this type of machine setup and enjoy the benefits they bring, such as production solutions, efficiency, and product quality.

2.4 High quality surface effect

This type of configuration also helps create surfaces with high-quality smoothness. The position of the parts is closer to the cutting tools in the 5-axis machine tool. The last two axes will allow one person to use a short cutting tool that will not vibrate too much, resulting in high-quality surface finish.

Another advantage of 5-axis CNC machine tools is that they can cut complex shapes. All five axes require various parts. The additional motion in this type of arrangement provides space for creating angles and arcs. Previously, they would require additional settings and unique fixtures.

2.5 High production efficiency

Five axis machining can effectively reduce the processing time and auxiliary time of parts. It has a wide range of spindle speeds and feed ranges, giving the machine powerful cutting capabilities. Five axis machining is entering the era of high-speed machining. The rapid movement and positioning of 5-axis machining and high-speed cutting machining reduce the turnover time of semi-finished products and improve production efficiency and accuracy.

2.6 Competitive Advantage

Very few factories use 5-axis CNC machine tools. Setting up once will give you an advantage over your competitors in terms of production services. You can provide customers with services that competitors cannot offer. You should try this type of machine setup and enjoy the benefits they bring, such as production solutions, efficiency, and product quality.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque