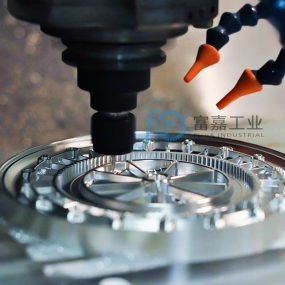

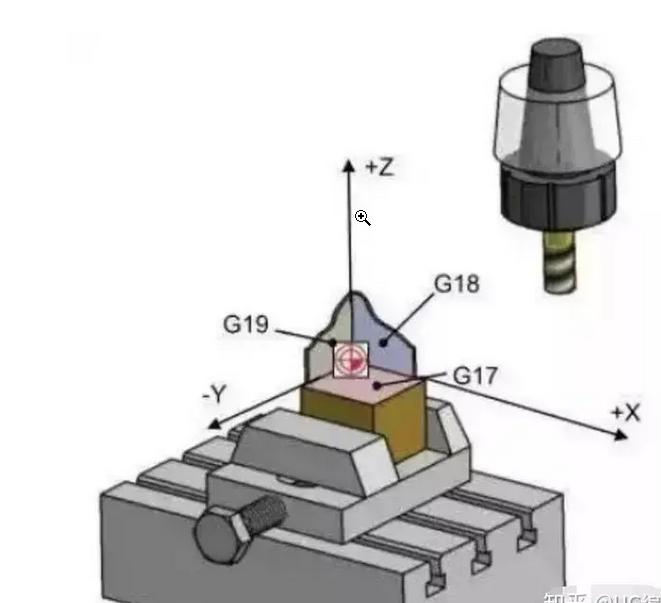

1、 Introduction to Programming Methods: A CNC machine tool is a type of machine tool that relies on a digital control system to automatically control mechanical motion and process parts. In CNC machine tools, program instructions are input to enable the machine to perform machining operations on the workpiece. There are many methods for programming CNC machine tools, but the most commonly used one is the three-axis programming method. Three axis control refers to the control of the position and shape of the workpiece processed by controlling the three directional movements of the CNC machine bed. The three axes are X, Y, and Z, respectively. The X-axis represents the direction of movement on the workpiece bed, the Y-axis represents the left and right directions, and the Z-axis represents the up and down directions. 2、 Programming step instructions: 1. Zeroing operation Before programming, it is necessary to perform a zeroing operation, which means that the coordinate axis of the CNC machine tool returns to its initial state. 2. There are generally two ways to choose a coordinate system for CNC machine tools: absolute coordinate system and relative coordinate system. The absolute coordinate system calculates the machining position based on a fixed point on the machine tool workbench as the coordinate origin. The relative coordinate system determines the coordinate origin with the machining starting point as the reference point, and calculates the machining position based on this. 3. There are two interpolation methods to choose: linear interpolation and circular interpolation, which are used for machining straight lines and curves, respectively. Among them, arc interpolation includes two directions: clockwise and counterclockwise. 4. Write a program based on the machining requirements of the workpiece. Programming should follow the machining principle of fast followed by slow, coarse followed by fine, and small followed by large. 5. Input and start the program. Input the written program into the CNC machine tool and start the program. Note that the program needs to be preprocessed and checked before starting.

3、 Programming precautions: 1. Program input should pay attention to the correctness of syntax format and instructions. 2. When compensating for coordinates and tool length, it is necessary to set them according to the regulations provided by the machine tool manufacturer. 3. For more complex processing, multiple trial cuts are required to determine parameters and compensation values before it can be put into formal production. 4. During the processing, observation should be carried out to adjust the processing parameters in a timely manner. 5. Before starting the program, safety measures and inspections should be taken to ensure safety during the processing.

In short, CNC machine tool programming is an important technical activity that requires proficiency in certain knowledge. Only practice makes perfect, and continuous practice and summary of experience can write higher quality programs. I hope the above content is helpful to everyone.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque