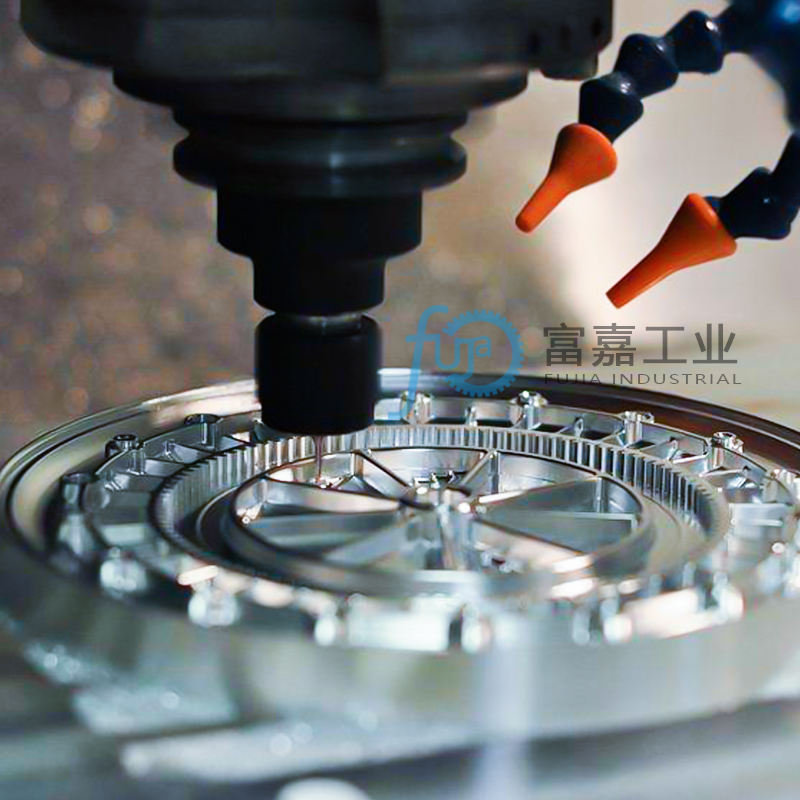

Numerical control milling is a process of milling through computer-controlled machine tools, and its advantages are mainly reflected in the following aspects:

1. High degree of automation: CNC milling machines can automatically complete the machining process through pre-set programs without manual intervention, greatly improving production efficiency and product quality.

2. High precision: CNC milling machines have high-precision machining capabilities, which can achieve precise machining of complex parts, ensuring the accuracy and stability of products.

3. High processing efficiency: CNC milling machines have the ability of high-speed processing, which can quickly complete the machining of parts, shorten the production cycle, and improve production efficiency.

4. Strong flexibility: CNC milling machines can be flexibly adjusted according to different processing requirements, adapting to the processing of various complex shapes and sizes of parts.

Numerical control milling is mainly applied in the following fields:

1. Aerospace field: CNC milling is widely used in the aerospace field for manufacturing complex parts such as aircraft and missiles.

2. Automotive manufacturing: CNC milling is widely used in the field of automotive manufacturing, for processing automotive engines, transmission systems, and body components.

3. Electronic communication: CNC milling is also widely used in the field of electronic communication, for processing mobile phones, tablets, and electronic components.

4. Mechanical manufacturing: CNC milling is widely used in the field of mechanical manufacturing, for processing various mechanical parts and equipment.

Overall, CNC milling has advantages such as high efficiency, high precision, and high stability, and is widely used in various fields of parts processing, playing an important role in improving product quality and production efficiency. With the continuous development of technology, CNC milling technology will continue to improve and develop, providing more efficient and precise machining solutions for various industries.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque