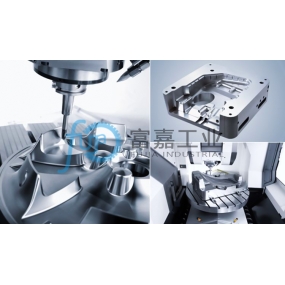

Numerical control machining is a high-precision and high-efficiency machining method that is widely used in industrial production. Numerical control machining of parts is carried out automatically by computer-controlled machine tools, which has the advantages of high precision, good repeatability, and fast processing speed. The general process and specific steps of CNC Machining will be introduced below.

1、 General process of CNC machining

1. Determine the design requirements, material and process requirements for the processed parts.

2. Write numerical control programs, including parameters such as tool path, speed, and feed rate.

3. Set up machine tools and fixtures, and prepare cutting tools and workpieces.

4. Load the CNC program, debug the machine tool, and test its operation.

5. Carry out processing, monitor the processing process, and adjust parameters in a timely manner.

6. Complete processing, conduct quality inspection, and clean parts.

2、 Specific steps of CNC machining

1. Design processing plan: Firstly, it is necessary to determine the design requirements for the processed parts, including size, shape, surface roughness, etc. Write numerical control programs according to design requirements.

2. Writing numerical control programs: Numerical control programs refer to converting machining process requirements into instructions that machine tools can recognize and execute through programming languages. The program includes parameters such as tool path, cutting speed, feed rate, cutting depth, etc.

3. Set up machine tools and fixtures: Select appropriate machine tools and fixtures according to the requirements of the CNC program, and install the cutting tools and workpieces.

4. Load CNC program: Transfer the written CNC program to the machine tool control system through CAD/CAM software and set the machine tool parameters.

5. Debugging the machine tool: Conduct an idle running test to check whether the various components of the machine tool are operating normally. If there are any abnormalities, adjust them in a timely manner.

6. Processing: Start actual processing, monitor the processing process, and ensure processing quality.

7. Completion of processing: After processing is completed, quality inspection is carried out to check the dimensions, surface quality, parallelism and other indicators of the parts.

8. Cleaning parts: Clean the processed parts to remove chips and oil stains.

In short, CNC machining is a high-tech processing method that requires a certain level of CNC programming and machine tool operation skills. Through scientific processing techniques and strict operating procedures, the quality and efficiency of CNC machining can be ensured. I hope the above content can be helpful to you.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque