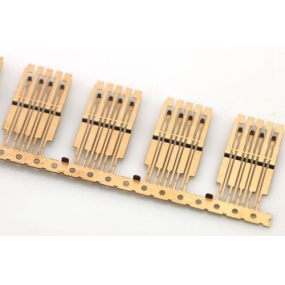

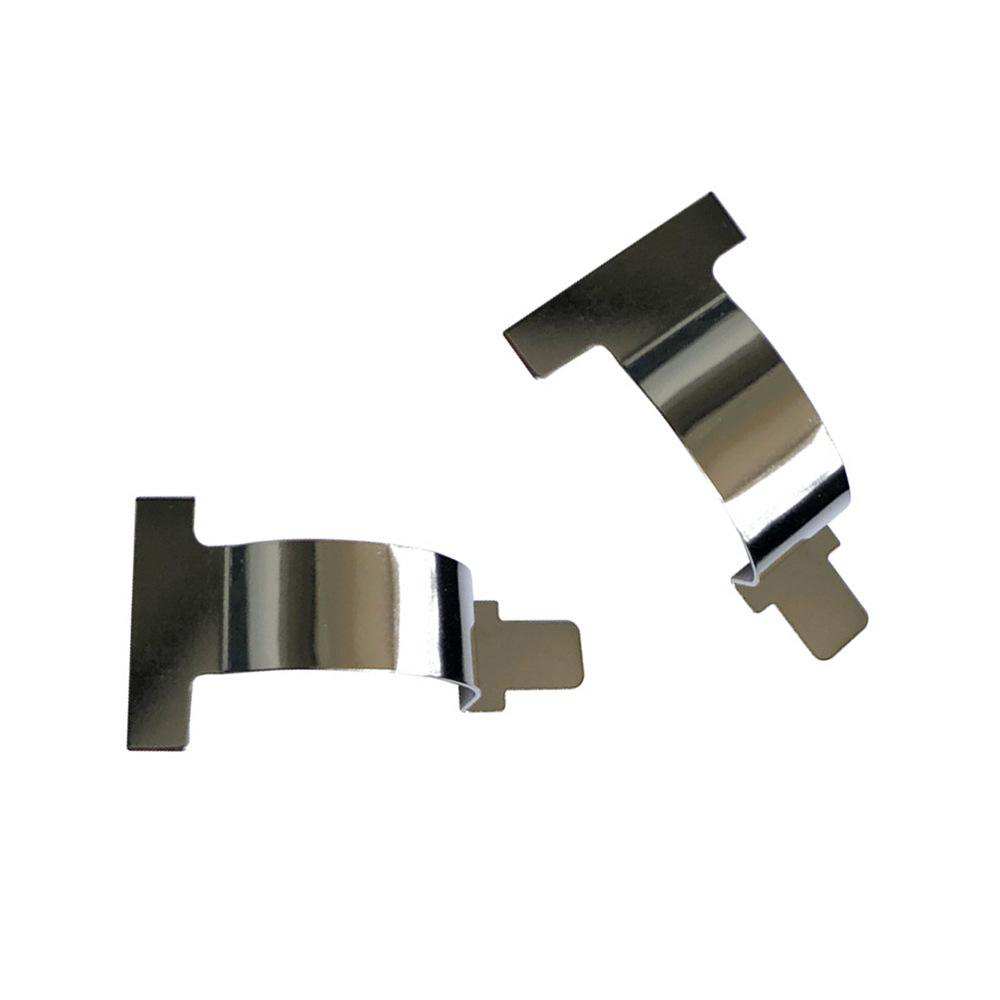

Many existing hardware components are applied to electronic product structures, such as square shell battery sealing aluminum nails. These precision stamped hardware components are widely used in daily life, with high precision requirements and strict appearance requirements. Therefore, large-scale production solutions are often preferred. Because the aluminum nails used for sealing square shell batteries are small in size and lightweight, they can save material and production costs.

Precision Metal Stamping materials have a wide range, mainly including non-ferrous metals such as carbon steel, alloy steel, stainless steel, and plastics. The main points of its mold processing are as follows: (1) the thickness tolerance of the sheet metal and the dimensional tolerance of the punched part are relatively small during punching; (2) The surface of precision metal stamping and cutting parts is smooth; (3) Due to accurate blank dimensions and high material utilization, zero waste can be achieved; (4) The dimensional accuracy, shape accuracy, and surface quality of the punched parts are high, and the interchangeability is good; (5) The punching mold has a complex structure and moderate manufacturing cost.

However, generally speaking, low-carbon steel has good stamping performance, while stainless steel has poor stamping performance. The stamping performance of non-ferrous metals is between the two, with plastic having poor stamping performance.

Although there may be some common defects during the stamping process of precision hardware parts, such as size deviation and increased scrap rate. But when processing and producing hardware such as aluminum nails for sealing square shell batteries, precision is generally required to be qualified, and the quality requirements for cutting parts are also high. The accuracy of their size and shape is also guaranteed. Therefore, when producing lightweight hardware such as aluminum nails for sealing square shell batteries, batch production is preferred to reduce the scrap rate.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque