Many CNC processing manufacturers have been seeking to control the cost of CNC processing as much as possible. Many users have also found that the quotes given by different companies for the same product can vary greatly. What are the main reasons for this? Setting aside factors such as factory size and location, how can we better control the cost of CNC processing? Shenzhen EMAR Precision Technology has been committed to high-precision CNC Machining for more than ten years. Next, we will share with you which factors can cause abnormal noise in CNC machining costs. Let's learn together.

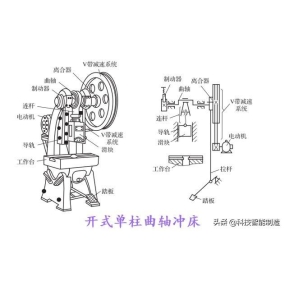

1. The demand for precision machining equipment

The prices of different production equipment are definitely different, which leads to differences in labor costs. For example, a 200000 yuan equipment and a two million yuan processing equipment will definitely have a significant price difference. Writing with multiple devices to complete a product and using one device with multiple functions to complete a product may result in price differences due to different processing functions of the equipment. For example, the cost of using a combination of lathe and CNC milling machine for precision turning and milling machining parts is definitely higher than that of an economical turning and milling composite machining machine. However, if both the lathe and milling machine are used in older or less branded machinery, the cost of cheaper equipment is relatively low. Some larger companies require high-precision testing equipment to assist them due to the high requirements of the products they come into contact with, which invisibly increases the cost of using the equipment.

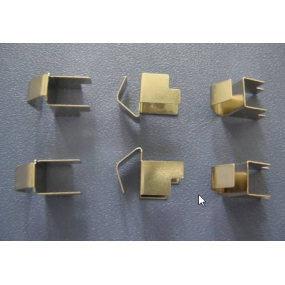

2. The size and shape of the parts

The size and shape of the parts themselves, as well as the precision parts with large volume and complex shape, will result in a large processing part, which will naturally increase the use of materials and waste generated during processing. Some users have special requirements for the smoothness of the product, so the cost will also increase.

3. Subsequent processing after precision machining

Many users' products require subsequent processing due to their involvement in different fields, such as oxidation, spraying, heat treatment, etc. These processes are also an aspect of increasing product costs. Therefore, engineers need to conduct sufficient evaluation of the product and measure its cost-effectiveness when designing it.

In summary, if cost control is necessary, choosing appropriate precision machining processes, equipment, materials, and outsourcing cooperation is the best way to effectively control costs. Do not easily adopt a certain company's processing costs because they are particularly cheap.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque