Milling machine processing is a common mechanical processing method, and it is very important to choose the appropriate milling machine processing method in different workpiece processing processes. To choose a suitable milling machine processing method, the following aspects need to be considered:

Firstly, the material of the workpiece should be considered. Different materials of workpieces require different milling methods. For materials with high hardness and brittleness, top feed milling can be chosen to reduce thermal deformation on the workpiece surface and vibration during cutting. For soft materials or materials that are prone to deformation, the side feed method can be chosen for milling to improve processing efficiency and surface quality.

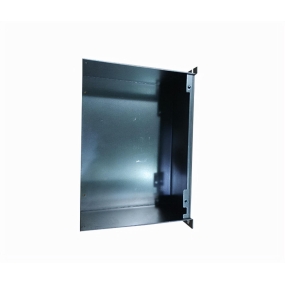

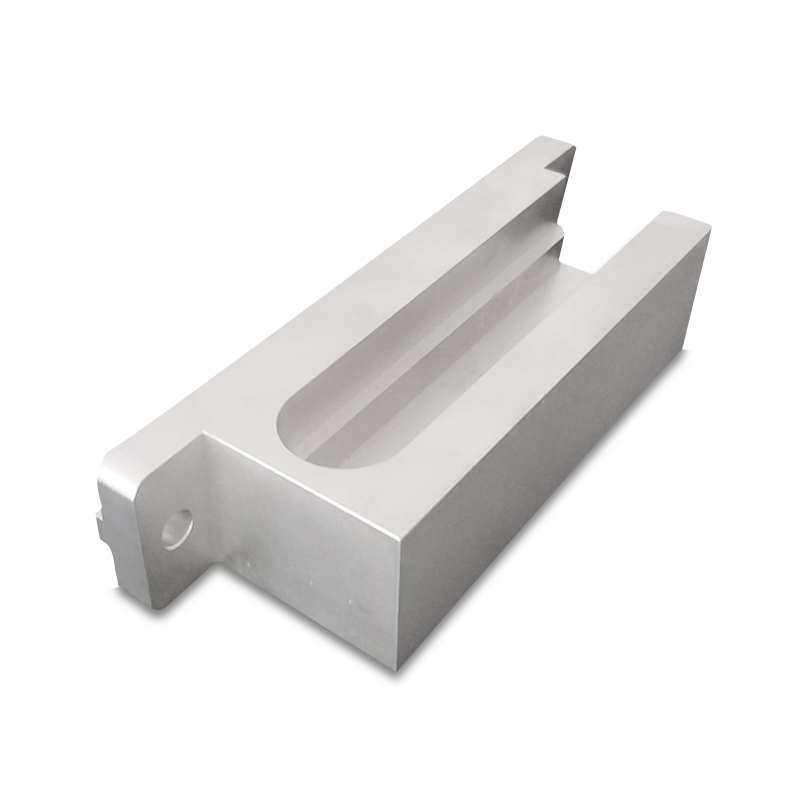

Secondly, the shape and size of the workpiece should be considered. For workpieces with complex shapes and large sizes, CNC milling machines can be used for processing, and the motion trajectory of milling tools can be controlled by CNC programs to achieve high-precision and high-efficiency machining. For small-sized workpieces, manual milling machines can be chosen for processing, with high flexibility and suitable for small batch production.

Again, it is necessary to consider the precision and surface quality requirements of the processing. Different processing methods will have an impact on processing accuracy and surface quality. In the pursuit of precision and surface quality, advanced milling techniques such as high-speed cutting and dry cutting can be chosen to improve machining accuracy and surface quality. For workpieces with general requirements, conventional cutting methods can be chosen for processing.

Finally, processing efficiency and cost should be considered. Different milling methods may have certain differences in processing efficiency and cost. Generally speaking, using CNC milling machines for machining can improve machining efficiency and reduce labor costs. However, the purchase and maintenance costs of CNC equipment are relatively high. Therefore, when choosing a milling machine processing method, factors such as processing efficiency, cost, and workpiece quality should be comprehensively considered, and the selection should be based on specific processing requirements.

In general, choosing a suitable milling machine processing method requires comprehensive consideration of factors such as material, shape, size, accuracy, surface quality, efficiency, and cost. Reasonable selection should be made according to specific situations in order to achieve efficient and high-quality processing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque