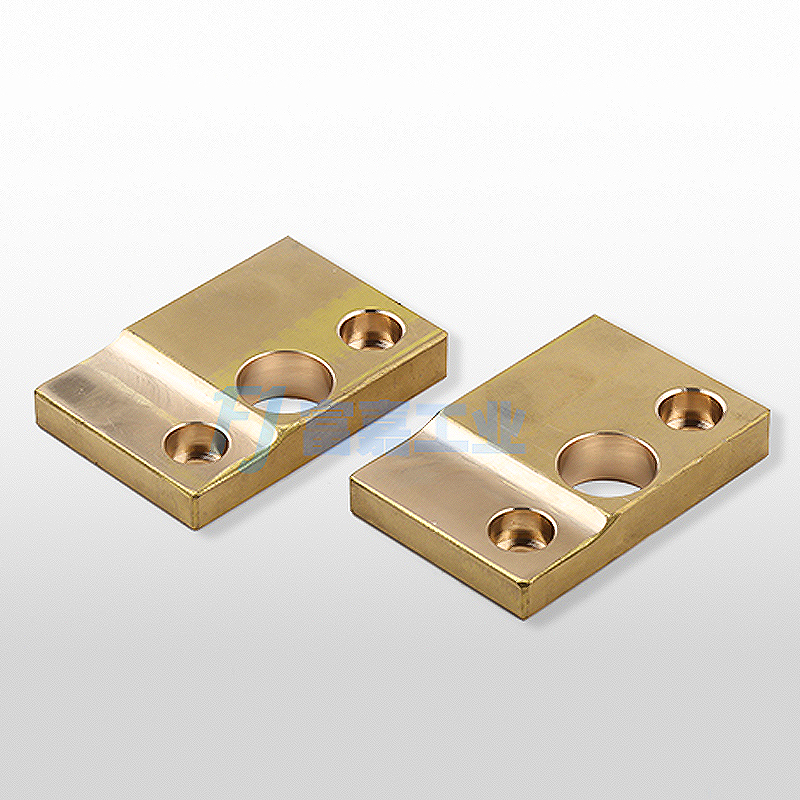

Copper CNC Machining technology refers to a process of processing copper materials using computer numerical control technology. Copper CNC machining technology has the characteristics of high precision, high efficiency, and high stability, and is widely used in fields such as automotive, aerospace, electronics, and machinery. Copper CNC machining technology mainly includes copper processing technology, processing equipment, processing tools, and processing accuracy.

Firstly, the machining process of copper parts CNC machining technology mainly includes workpiece design, machining process planning, CNC programming, process testing, and process optimization. The design of workpieces is to meet the functional requirements and structural specifications of copper parts, and must take into account the mechanical properties and processing characteristics of copper materials. Process planning is to determine the machining route, machining sequence, cutting parameters, etc., to ensure the machining quality and efficiency of the workpiece. Numerical control programming is the process of writing numerical control programs based on the geometric shape and dimensional data of the workpiece, ensuring that the CNC machine tool processes according to the predetermined path and speed. Process testing is conducted to verify the feasibility and effectiveness of processing techniques, further optimize process parameters, and improve processing quality and efficiency.

Secondly, the processing equipment for copper CNC machining technology mainly includes CNC lathes, CNC milling machines, CNC electric discharge machines, etc. A CNC lathe is a CNC machine tool used to machine cylindrical parts, which achieves turning of workpieces through the rotational motion of cutting tools on the workpiece. Numerical control milling machine is a CNC machine tool used to process flat and curved parts. It achieves milling of workpieces through the rotation of cutting tools on the workpiece and the relative motion of the workpiece. Numerical control electric discharge machine is a CNC machine tool used to machine complex contours and high-precision parts. It achieves discharge machining of workpieces through the discharge of electrodes on the workpiece.

Again, the processing tools for copper CNC machining technology mainly include high-speed steel cutting tools, hard alloy cutting tools, diamond cutting tools, etc. High speed steel cutting tools are suitable for processing general copper parts and have the advantages of fast cutting speed and long service life. Hard alloy cutting tools are suitable for processing hard copper parts and have the characteristics of high cutting force and strong wear resistance. Diamond cutting tools are suitable for processing high hardness copper parts and have the advantages of high cutting accuracy and processing efficiency.

Finally, the machining accuracy of copper CNC machining technology mainly includes surface roughness, dimensional accuracy, and form and position tolerances. Surface roughness refers to the smoothness and flatness of the copper surface, which directly affects the appearance and performance of the workpiece. Dimensional accuracy refers to the tolerance control of the dimensional accuracy and geometric shape of copper parts, which is directly related to the assembly and use of the workpiece. Geometric tolerance refers to the tolerance requirements for the shape, position, and orientation of copper parts, which directly affect the functionality and reliability of the workpiece.

In summary, copper CNC machining technology is a high-precision, high-efficiency, and high stability machining technology with important application prospects and market demand. With the continuous advancement of technology and the continuous development of the market, CNC machining technology for copper parts will be further improved and promoted, making positive contributions to the development and progress of China's processing and manufacturing industry.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque