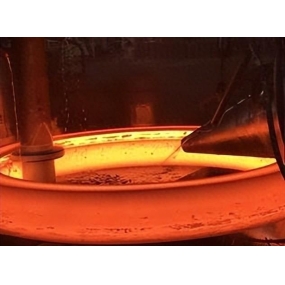

The manufacturing industry in China is so powerful that the division of labor is becoming increasingly detailed. The smart approach of powerful companies is not to do everything, but to master core technology and outsource ordinary production to the most professional factories! EMAR hardware is a precision manufacturing division within the cold extrusion manufacturing industry! To be honest, there may be tens of thousands of factories in China that do ordinary cold extrusion, but there are not many factories in China that do micro precision cold extrusion. EMAR Hardware has been developing precision cold extrusion technology for the production of micro hardware electronic parts since 2010. The successful development of continuous cold extrusion production technology in 2012 has greatly improved product quality and production efficiency. The product precision has reached 0.02mm, and the product output can reach 200000 particles per day, achieving good economic and social benefits. Many products serve many Fortune 500 companies! Due to the fine division of labor in the manufacturing industry, precision cold extrusion technology is a niche field. There are not many companies that EMAR Hardware can refer to in the manufacturing of precision cold extrusion technology. Therefore, not only can they challenge themselves through customers' "excessive" requirements, but now precision cold extrusion products are becoming smaller and smaller, with a minimum volume of 0.2 * 0.2 * 0.2mm. The daily output of single-mode products has also increased from 50000 particles per day to 200000 particles per day, and the frequency of mold maintenance has changed from 3 days to 20 days! All achievements cannot be achieved without the technical and experience accumulation of engineers! Precision cold extrusion technology, EMAR is able to mature through continuous self challenge!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque