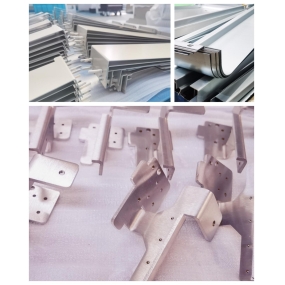

When it comes to connecting conductive sheets, many people are not very familiar with it. In lithium batteries, connecting conductive sheets plays a very important role. Copper conductive soft connections and aluminum foil soft connections can be customized according to the length, width, and thickness provided by customers, as well as the requirements of the process. This type of connecting conductive sheet has different names in different requirements and fields.

The current technologies available in the market include the following: 1. High quality 0.05-0.3mm thick aluminum foil is pressed together, followed by molecular diffusion welding, which is formed by high current heating and pressure welding. Silver based brazing material is used to butt weld with flat aluminum blocks. 2. This connection has the characteristics of good conductivity, high precision, and lightweight. Both the appearance and the connection appearance are relatively flat, and the specifications are complete and can be customized for processing.

This type of connecting conductive sheet is widely used in daily life, in industries such as transformer installation, high and low voltage switchgear, vacuum appliances, etc. The use of connecting conductive sheets can improve conductivity, adjust equipment installation errors, provide shock absorption, and facilitate testing and equipment maintenance.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque