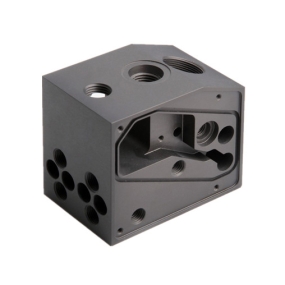

Large scale CNC Machining, especially CNC high-speed machining centers and CNC large-scale engraving and milling machines, have demonstrated significant machining advantages in modern manufacturing. Here are the specific manifestations of these advantages: 1 High precision machining and micrometer level machining capability: Large CNC machining equipment, such as CNC large engraving and milling machines, use advanced CNC systems to achieve micrometer level high-precision machining. Whether it's complex surfaces, subtle holes, or high-precision contours, they can be easily handled to ensure machining quality. High positioning accuracy and repeatability accuracy: CNC high-speed machining centers achieve high positioning accuracy and repeatability accuracy through digital control technology, ensuring the dimensional and shape accuracy of processed products. 2. High efficiency production, fast feed and cutting capability: Large CNC machining equipment has a fast feed system and powerful cutting capability, which can complete the processing of a large number of workpieces in a short period of time. At the same time, they are usually equipped with multiple automatic tool changing devices, which can complete tool replacement in a short period of time, further improving production efficiency· 24-hour uninterrupted operation: These devices can achieve 24-hour uninterrupted operation, greatly improving production efficiency and meeting the modern manufacturing industry's demand for efficient production. 3. High flexibility processing and quick adaptation to different types of parts: Large CNC machining equipment can quickly adapt to the processing of different types of parts, and can achieve the processing of different products by simply changing the control program, with high production flexibility· Programming control flexibility: Through programming control, it is easy to achieve workpiece processing of different shapes, sizes, and materials, further expanding the processing range. 4. High degree of automation and reduced labor costs: Large CNC processing equipment can achieve unmanned long-term operation, greatly reducing labor costs and minimizing the impact of human errors. (Source: Machine Tool Network) · Intelligent Operation: With the development of technology, some CNC machining equipment has also integrated intelligent operation functions, such as automatic detection, automatic adjustment, etc., further improving machining efficiency and accuracy. 5. Environmental protection and energy-saving design: Large CNC machining equipment is designed with energy-saving and environmental requirements in mind, such as using servo motors to reduce energy consumption and using cutting fluid recovery systems to reduce pollution· Low noise operation: By optimizing design and adopting noise reduction technology, these devices have lower noise levels during operation and have less impact on the working environment· 6. Wide application fields and multi industry applications: Large CNC machining equipment is widely used in many industries such as aerospace, automotive manufacturing, mold manufacturing, precision instruments, etc., playing an indispensable role· Adapt to complex materials: These devices can process a variety of materials, including metals, plastics, composite materials, etc., meeting the needs of different industries for complex material processing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque