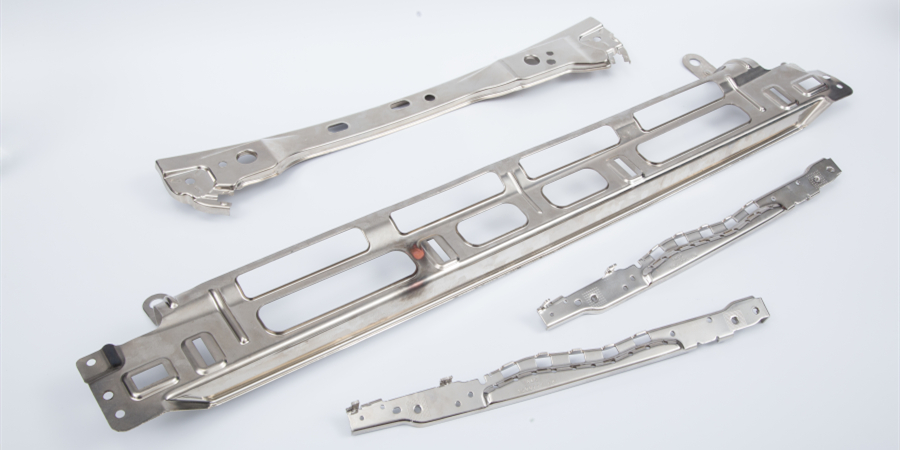

Stamping parts processing manufacturers, processing Metal Stamping parts, stainless steel stamping parts, shaped parts, etc. With the development of society, the mold profession has developed rapidly and can be used in various industries. The installation and disassembly of molds also require a certain order. Below is a brief understanding of the disassembly order of metal stamping parts molds:

1. Square the metal stamping die on the fitter's table, and use both hands to hold the small die near the guide sleeve of the upper template, then lift it up with force to separate the upper and lower molds. If it is impossible to separate, one person can lift the entire mold slightly away from the desktop and suspend it, while the other person can use a copper rod to tap around the template material in one go to make it detach. Note that the upper mold after separation should be placed flat on the side to avoid damaging the cutting edge of the mold;

2. Clamp the upper mold horizontally onto the vise (note that only the template part can be clamped), use a hex wrench to unscrew the fastening screws of the mold handle, concave mold fixing plate, and concave film at once, and then punch out the pin. The upper mold part can be decomposed into individual die parts;

3. The disassembly of the lower mold is basically the same as that of the upper mold. Remove the elastic unloading plate screws (insert an Allen wrench from the lower cheek direction of the lower mold), remove the unloading rubber, and then remove the screws and pins of the convex and concave molds. At this point, the disassembly of the lower mold is completed;

4. Measure the cutting edge dimensions including convex and concave molds with a vernier caliper and record them.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque