Characteristics and application analysis of laser cutting in Shenyang.

The concept of stimulated light radiation proposed by Einstein in the 1920s foresaw the emergence of lasers. In 1960, American scientist Meiman successfully developed a ruby laser, marking the official birth of lasers. Subsequently, laser technology developed rapidly. After solid-state lasers, gas lasers, chemical lasers, dye lasers, atomic lasers, ion lasers, semiconductor lasers, X-ray lasers, and fiber lasers have successively emerged, and their application fields have also expanded to electronics, light industry, packaging, gifts, small hardware industry, medical equipment, automobiles, machinery manufacturing, steel, metallurgy, petroleum, etc., providing technical equipment for the technological transformation of traditional industries and the modernization of manufacturing.

Laser has four characteristics compared to ordinary light: monochromaticity (single wavelength), coherence, directionality, and high intensity. Laser beams are easy to transmit, and their time and spatial characteristics can be controlled separately. After focusing, extremely small light spots can be obtained. Laser beams with power density can melt and vaporize any material, and can also quickly process local areas of materials. The heat input to the workpiece during the processing is small, and the heat affected zone and thermal deformation are small; High processing efficiency; Easy to implement automation. Laser technology is a comprehensive high-tech field that involves disciplines such as optics, mechanics, and electronics. Similarly, laser processing equipment also involves numerous disciplines, which determines its high-tech nature and high profitability. Through years of research and development, as well as improvement in the domestic laser application situation, contemporary lasers and laser processing technologies and equipment have become quite mature, forming a series of laser processing processes.

Now, the editor of Shenyang Laser Cutting will introduce the application of laser processing technology in metal cutting.

1. Characteristics and Applications of Laser Cutting

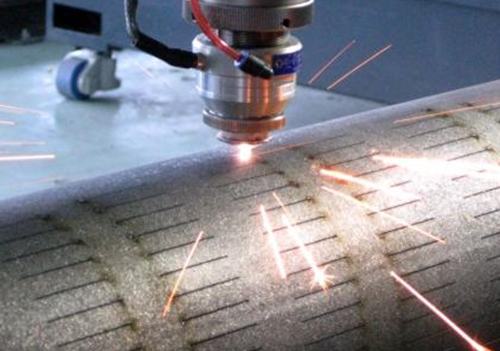

Laser cutting is currently a widely used laser processing technology in various countries. In many fields abroad, such as automobile manufacturing and machine tool manufacturing, laser cutting is used for the processing of sheet metal parts. With the continuous improvement of the beam quality of high-power lasers, the range of processing objects for laser cutting will become more extensive, including almost all metal and non-metal materials. For example, laser cutting can be used to cut complex three-dimensional parts of materials with high hardness, brittleness, and melting point, which is also the advantage of laser cutting.

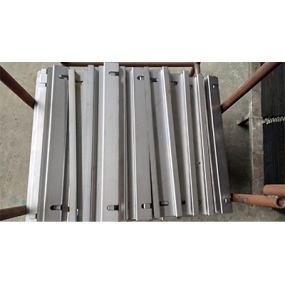

Shenyang laser cutting

Nowadays, enterprises that choose laser cutting systems are mainly divided into two categories: one is large and medium-sized manufacturing enterprises, which produce a large number of sheets that need to be cut and cut, and have strong economic and technological strength; The other type, collectively known as processing stations, specializes in undertaking laser processing business externally. Its existence can meet the processing needs of some small and medium-sized enterprises on the one hand, and on the other hand, it plays a role in promoting and demonstrating the application of laser cutting technology in the early stage.

The key technologies of laser cutting are the integrated technology of light, machine, and electricity. The parameters of the laser beam, as well as the performance and accuracy of the machine and CNC system, directly affect the efficiency and quality of laser cutting. The accuracy, efficiency, and quality of laser cutting vary with different parameters, such as cutting power, speed, frequency, material thickness, and material, so the rich experience of operators is particularly important.

1.1 Main advantages of laser cutting

(1) Good cutting quality: narrow incision width (generally 0.1-0.5mm), high precision (generally hole spacing error 0.1-0.4mm, contour size error 0.1-0.5mm), good surface roughness of the incision (generally Ra 12.5-25 μ m), and the incision generally does not require secondary processing for welding.

(2) Fast cutting speed, for example, using a 2kW laser power, the cutting speed of 8mm thick carbon steel is 1.6m/min; The cutting speed of stainless steel with a thickness of 2mm is 3.5m/min, with a small heat affected zone and minimal deformation.

(3) Clean and pollution-free, greatly improving the working environment for operators.

Laser cutting belongs to non-contact optical thermal processing and is known as a "wear-resistant tool". Workpieces can be tightly packed or cut in any form to fully utilize raw materials. Due to non-contact processing, the distortion of the processed parts is reduced to a lower level and the amount of wear is minimized.

In fact, laser cutting also has its shortcomings. In terms of accuracy and cutting surface roughness, laser cutting has not surpassed electrical machining, and in terms of cutting thickness, it is difficult to reach the level of flame and plasma cutting. In addition, it cannot perform molding, tapping, and folding like a turret punch press.

1.2 Comparison between laser cutting and punch press

Previously, the Sheet Metal Processing industry used traditional punching machines for stamping, but later developed into CNC turret punching machines and composite machine tools. With the progress of society, laser cutting technology has also been introduced into the metal processing industry, and has become a rapidly developing and widely used processing method for sheet metal cutting in industry. According to informal statistics, China has accumulated over 500 laser cutting systems used in industrial production, accounting for approximately 2% of the world's total operating systems.

In the metal processing industry, laser cutting is widely used for low carbon steel with a thickness of no more than 20mm and stainless steel with a thickness of 8mm. Most of the sheet metal parts have complex contour shapes and small batch sizes, such as automatic elevator structural parts, elevator panels, machine tool and grain machinery covers, various electrical cabinets, switch cabinets, textile machinery parts, engineering machinery structural parts, large motor silicon steel sheets, etc. In addition, some metal patterns, logos, and fonts used in decoration, advertising, and service industries can also be manufactured using laser cutting.

The CNC brick tower punching machine is suitable for mass production of products with simple shapes. The finished products include electrical cabinets, communication system exchange cabinets, elevator door panels and handrail panels, steel furniture, etc. Compared with CNC brick tower punching machines under the same cutting and stamping conditions, laser cutting machines are generally more expensive, but due to their flexibility and other advantages (such as laser cutting only needs to cut according to the drawing shape, and there is no need to manufacture molds, which shortens the production cycle). In recent years, some manufacturers have gradually realized the high benefits it brings. In order to enhance market competitiveness, companies have purchased laser cutting machines to adapt to various types of products while owning multiple CNC brick tower punching machines. So, rather than saying that laser cutting machines compete with CNC brick tower punching machines, it is more appropriate to say that they complement each other.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque