Using a high-energy density laser beam to heat the workpiece rapidly increases the temperature, reaching the boiling point of the material in a very short period of time, and the material begins to vaporize, forming vapor. The ejection speed of these vapors is very high, and at the same time as the vapors are ejected, incisions are formed on the material. With the continuous development of the storage tank industry, more and more industries and enterprises are using laser cutting (3 sheets) for storage tanks. More and more enterprises are entering the storage tank industry. However, due to the reduction of the cost of subsequent process processing, it is still feasible to use this equipment in large-scale production.

brief introduction

Laser cutting equipment can cut stainless steel below 4mm, and adding oxygen to the laser beam can cut carbon steel with a thickness of 20mm. However, after oxygen cutting, a thin oxide film will form on the cutting surface. The cutting thickness can be increased to 20mm, but the size error of the cutting parts is relatively large.

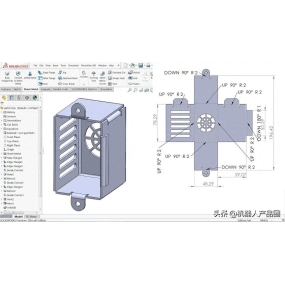

The price of laser cutting equipment is quite expensive, about 1.5 million yuan or more. However, due to the reduced cost of subsequent processing, it is still feasible to use this equipment in large-scale production. Due to the lack of cutting tool processing costs, laser cutting equipment is also suitable for producing small batches of various sizes of parts that could not be processed before. Laser cutting equipment usually uses computerized numerical control technology (CNC) devices, which can be used to receive cutting data from computer-aided design (CAD) workstations via telephone lines.

principle

Laser cutting is the use of a focused high-power density laser beam to irradiate a workpiece, causing the irradiated material to quickly melt, vaporize, burn, or reach the ignition point. At the same time, high-speed airflow coaxial with the beam is used to blow away the molten material, thereby achieving the cutting of the workpiece. Laser cutting is one of the thermal cutting methods.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque