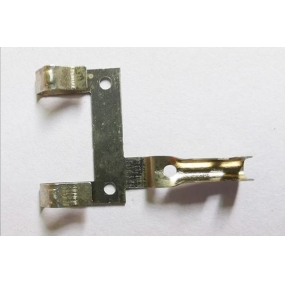

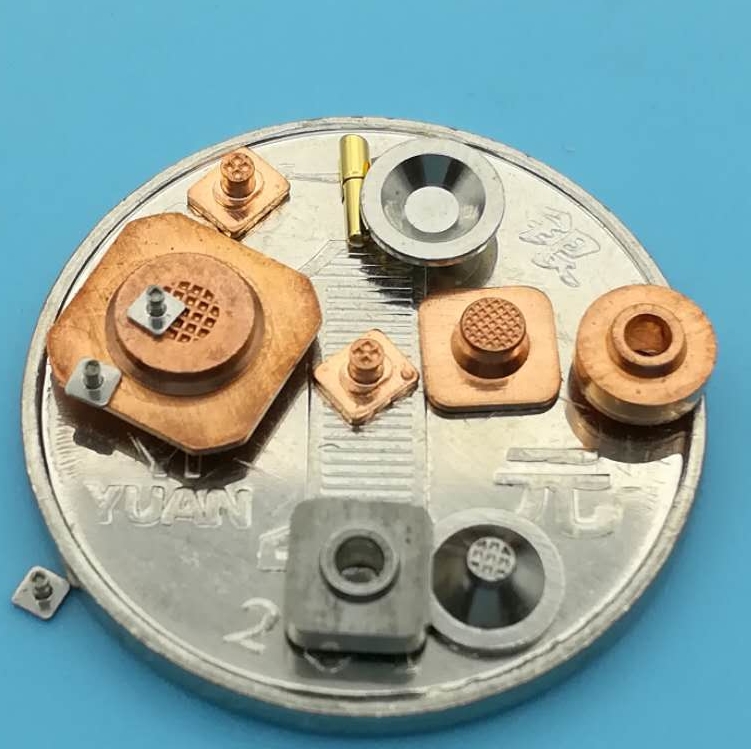

micro precision cold extrusion is a new branch of cold extrusion developed in the last three decades, mainly used in the field of microelectronic parts. With the development of electronic products towards miniaturization, the demand for micro hardware electronic parts is growing, and the product requirements are becoming more and more precise. Micro precision cold extrusion manufacturing is also playing an increasingly important role in the national economy. In combination with EMAR hardware's years of experience in micro precision cold extrusion production and research and development, I would like to talk about the precautions in the design of micro precision cold extrusion dies. I hope that old iron workers who are interested in developing in this field will not go wrong, and at the same time, technical leaders are welcome to participate in our discussion through microblog micro to jointly improve the technology of micro precision cold extrusion.

micro precision cold extrusion is a new branch of cold extrusion developed in the last three decades, mainly used in the field of microelectronic parts. With the development of electronic products towards miniaturization, the demand for micro hardware electronic parts is growing, and the product requirements are becoming more and more precise. Micro precision cold extrusion manufacturing is also playing an increasingly important role in the national economy. In combination with EMAR hardware's years of experience in micro precision cold extrusion production and research and development, I would like to talk about the precautions in the design of micro precision cold extrusion dies. I hope that old iron workers who are interested in developing in this field will not go wrong, and at the same time, technical leaders are welcome to participate in our discussion through microblog micro to jointly improve the technology of micro precision cold extrusion.

In terms of micro precision cold extrusion technology, it is still cold extrusion, but it is a micro and higher precision cold extrusion technology. Therefore, our production process still needs to refer to the production process of ordinary cold extrusion. Traditional cold extrusion is cutting cake, annealing, phosphating saponification treatment, composite extrusion, annealing, phosphating saponification treatment, extrusion molding, cutting and separation. Micro precision cold extrusion also cannot do without these processes. However, micro precision cold extrusion needs to continue these processes to make production more efficient and precise. Microelectronics precision cold extrusion parts can easily produce millions or even tens of millions of particles per order. If you are still using traditional cold extrusion manual loading methods for production, it's time to finish class early! So the research and production of micro precision cold extrusion technology have become increasingly important, which is why we need to talk about the topic of micro precision cold extrusion technology.

The design of micro precision cold extrusion molds should consider their continuous productivity, and the equipment used is also high-speed punching machines. Only high-speed punching machines can meet the large-scale production needs of customers. EMAR's mature molds currently maintain a punching speed of 260 times per minute, which can still meet the needs of most customers. The speed should not be too fast. If the speed is too fast, the cooling speed of the punch cannot keep up, and damaging the insert will not be worth the loss. The number of customers is too large, so we need to open a few more sets of molds! ha-ha!

The design of micro precision cold extrusion molds should consider their continuous productivity. The embryo needs to be formed in many steps inside the mold, because cold extrusion processing is not like stamping processing, and the pressure is very high, reaching more than 2000MP. Therefore, the guide columns must not be too small or too few. When you encounter product design, you must fully consider this point, otherwise the product production will be unstable for a period of time, and you cannot find the reason. EMAR's years of experience tell you this is very important!

The most important mold structure in the design of micro precision cold extrusion molds is how to accurately feed. If the feeding method is not precise, it will seriously affect the yield rate of the product. EMAR Hardware has taken many detours in this regard. Currently, two sets of feeding methods are used, and a patent certificate has been applied for this production method. Therefore, it is not convenient to disclose more information to avoid touching the line!

The design of micro precision cold extrusion molds still needs to follow the principles of cold extrusion design. Regardless of the convex and concave molds, the metal flow should be easy, especially the design of metal dead nodes should be smooth. If the effect cannot be achieved, it can be divided into multiple designs to gradually achieve the desired shape. Do not design in one step, otherwise the damage speed of the punch will make your repairman even more tired than a dog!

Lubrication is such a key factor in the production of micro precision cold extrusion, which seriously affects the life of the mold. EMAR hardware has made many detours in the R&D and production. Finally, it was the solutions given by professors of the Materials Research Institute of Shanghai Jiaotong University that solved these headache problems, basically replacing the phosphating and saponification lubrication process. Now the production is very smooth. In this regard, old irons need EMAR to provide assistance.

Old irons, I can only mention the matters that should be noticed in the design and production of micro precision cold extrusion die. Welcome to have orders in this regard and use EMAR hardware to help you produce, or pay a patent fee for the technology provided by EMAR hardware!

Existing EMAR precision cold extrusion production videos, welcome to visit!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque