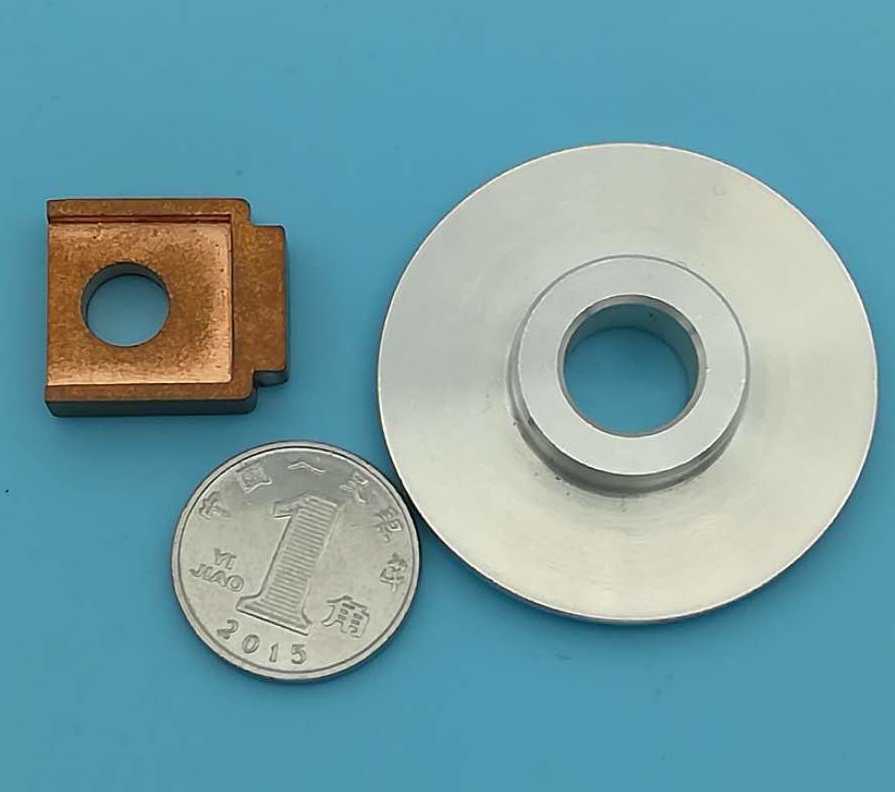

The continuous die high-efficiency cold extrusion production method has made it possible for new energy power battery charging piles to become ultra-low and inexpensive! With the increasing policy efforts of the country towards new energy electric vehicles, new energy vehicles are bound to experience explosive growth in the next 2-3 years. A recent customer contacted by EMAR stated that BMW and Mercedes Benz are in contact with them to develop new energy electric vehicles. The EMAR hardware has developed positive and negative electrode terminals for new energy power batteries, which are aluminum and copper products respectively. It is expected that the demand will reach 200000 to 600000 pieces per day next year. The customer is distressed that these two parts have been produced using CNC Machining, which not only cannot guarantee the production quantity in the future, but also cannot reduce the price. The customer saw our cold extrusion production process and approached EMAR Hardware with a try and see attitude to see if they could solve the confusion they are currently facing. EMAR Hardware organized mold designers to discuss product design solutions, and the result was: using precision continuous die cold extrusion production, the output and quality can be fully guaranteed, and the product price is one-third of the current CNC lathe production method price! The customer was overjoyed and said that the precision continuous die cold extrusion production technology has solved the bottleneck of mass production of new energy power battery charging piles. The amount of electric piles used for each vehicle is tens of thousands, and this technology solves the problems of cost and production speed. The speed of mass production of new energy vehicles will accelerate again, and China's manufacturing industry is really strong!

Continuous die cold extrusion production technology, EMAR hardware is always running! Welcome to the discussion on continuous die cold extrusion production technology! Let's make progress together!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque