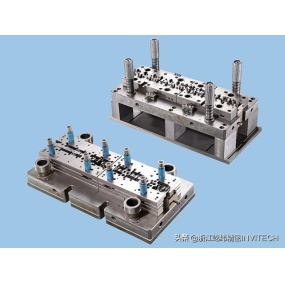

In the processing of many precision hardware components, there may be some problems, such as shrinking or thinning. For example, the precision mesh screen that we commonly see has this problem, which is a very common component in various fields of our lives.

Many times, mesh screens are made of stainless steel material. After processing, it may be found that their size is too small, which is different from the size that the user wants. This requires precise processing technology and precise data on size and dimensions.

Sometimes the low accuracy is also related to the design of the drawings. If the technical design does not match the processing technology, it will result in the size being too large or too small, which is not the precise size that the user wants. The duration of simultaneous processing is also related.

Therefore, in order to maintain precise tolerances for hardware precision mesh screens, engineering and technical personnel need to put effort into process design. In addition, technical personnel also need to operate according to strict standards in order to produce qualified precision mesh screen products for customers.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque