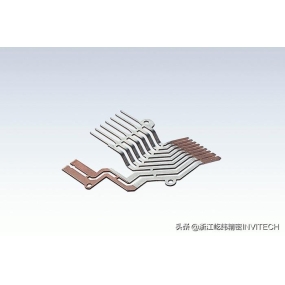

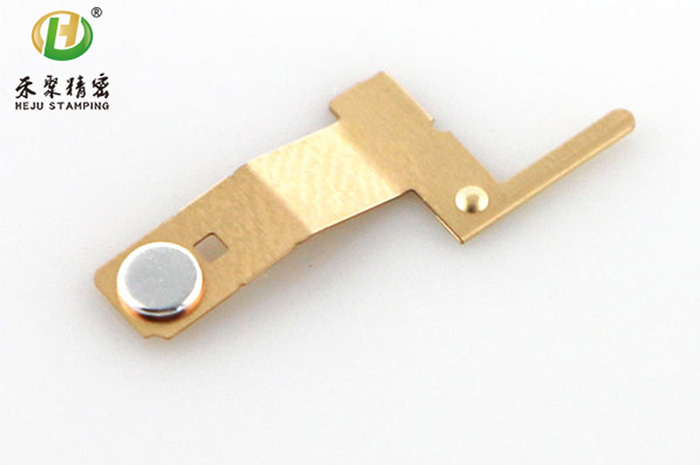

Stamping hardware is a common method in the manufacturing and production of hardware components. It is formed by using metal or non-metal sheet metal and stamping molds with the help of pressure from a press machine. For some people who may not be familiar with the manufacturing process of stamping hardware parts, let's briefly understand the process of stamping hardware parts through a few points.

EMAR Precision Stamping Hardware

The main characteristics of the stamping manufacturing process are:

1、 Determine the deformation compensation amount based on the material and product structure, then design the mold according to the compensation amount, and finally punch out the finished or semi-finished product.

2、 Secondly, from processing semi-finished products to finished products. Promptly detect any adverse phenomena, including cracks, wrinkles, uneven thickness, and non molding.

3、 In the process of tapping and threading, the inner thread first drills the diameter and depth of the bottom hole, while the outer thread first processes the outer circle to the larger diameter of the thread.

In the processing and manufacturing of stamping hardware, some materials with good ductility, such as metal or non-metal, are often chosen. Depending on the requirements, materials with low deformation resistance and good plasticity, such as copper, aluminum, and low carbon steel, are also selected. In the stamping process of stamped hardware parts, stamped parts need to be manufactured through stamping without significant material consumption, and can improve the strength of the stamped parts.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque