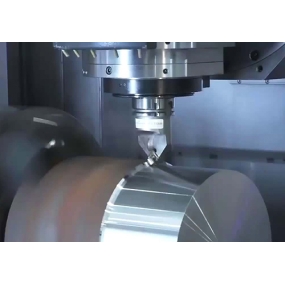

Titanium alloy CNC Machining is a high-precision and high-efficiency machining technology widely used in aerospace, medical, petrochemical and other fields. The process flow of titanium alloy CNC machining mainly includes the following steps: 1. Determine the part drawings and machining process requirements, and clarify the machining objectives. Conduct material procurement and inspection to ensure that the quality of titanium alloy materials meets the requirements Cut the material into appropriate sizes and perform surface cleaning treatment Design and manufacture CNC machining fixtures to secure titanium alloy workpieces and ensure stability during the machining process Write CNC machining programs, including parameters such as tool path, machining speed, and feed rate Perform machine tool clamping and debugging to ensure machining accuracy and stability Perform rough machining, first rough and then fine, to ensure that the workpiece has sufficient allowance Perform precision machining using appropriate tools and cutting parameters to meet design requirements Perform necessary heat treatment and surface treatment to improve the performance and surface quality of titanium alloy materials.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque