Many people do not have a deep understanding of stamping molds, so stamping processing plants are often questioned when negotiating cooperation with customers. Today, let's talk about the concepts of stamping technology and stamping molds for processing plants:

In modern industrial production, 60% to 90% of industrial products require mold processing. The mold industry has become the foundation of industrial development, and the development of many new products relies on molds, especially in industries such as automobiles, electronics, light industry, and aviation; Therefore, molds are important equipment for industrial production and the fundamental industry of the national economy; Mold is known as the "father of industry", and some people also call it the "mother of all industries". It is an industry that will never decline; The title given to molds by countries around the world: Japan - molds are the driving force for entering a prosperous society; Europe and America - Mold is a magnetic industry; Germany - Mold is the king of the metal processing industry, Romania - Mold is gold;

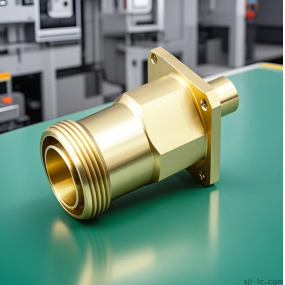

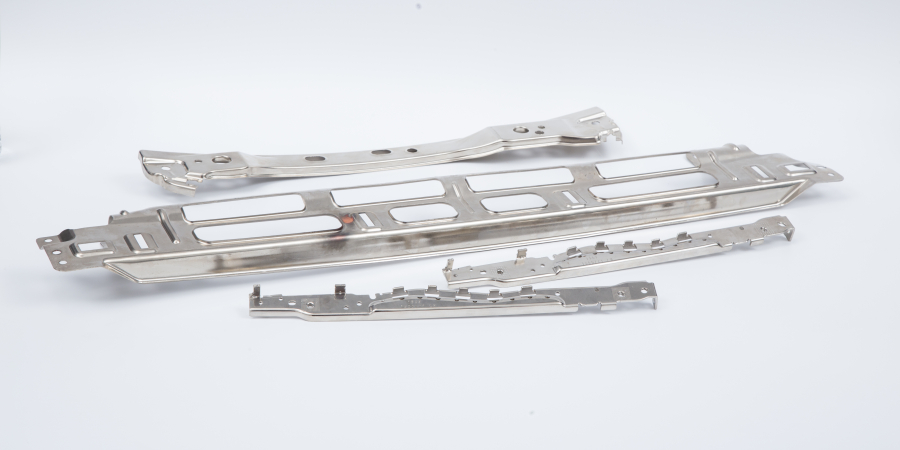

Stamping in stamping factories is a processing method that uses stamping dies to apply pressure (or tension) to sheet metal on stamping equipment, causing it to separate or deform, and then obtain a certain shape, size, and function of the workpiece;

The target of stamping processing in stamping factories is generally thin metal sheets (or strips), thin-walled tubes, thin materials, etc., and is therefore also known as sheet Metal Stamping. It is usually carried out at room temperature (without heating, clearly below the recrystallization temperature), and is therefore also known as cold stamping.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque