CNC walking machines and CNC milling machines both play a powerful role in the field of precision machining. Walking machines and CNC milling machines have their own special structures and face different industry fields. So, what is the difference between CNC milling machines and CNC walking machines?

The main difference between milling machines and lathes lies in the relationship between the workpiece and the cutting tool. Taking CNC milling machines and CNC centering machines as examples:

In a CNC lathe, the workpiece being machined rotates around its axis, while the cutting tool does not, which is called "rotation" and is effective for creating cylindrical components. Common operations performed on a lathe include drilling, boring, threading, ID and OD slotting, and cutting. When seeking fast, repeatable, and symmetrical cylindrical parts, a lathe is the best choice.

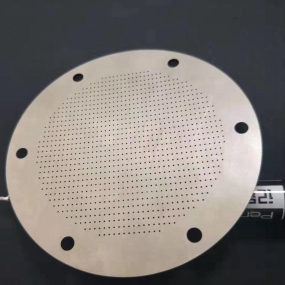

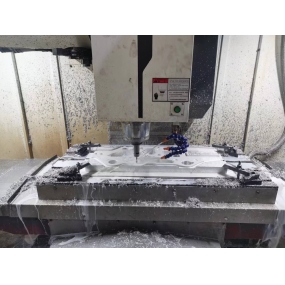

The tool in a milling machine rotates around its axis while the workpiece does not, allowing the tool to approach the workpiece in many different directions, which requires more complex and intricate components. If you can program it, as long as you have the appropriate gap and choose the appropriate tool, you can program it on the milling machine.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque