When it comes to stamping factories, everyone is familiar with them. For stamping factories, the design of stamped parts cannot be ignored, as it plays a very important role. The design of stamped parts directly affects the quality of hardware components, which is a crucial factor that cannot be underestimated.

How important is the design of stamped parts

It should be noted that reasonable design requires ensuring the necessary functions of the product, as well as reducing manufacturing costs to improve efficiency.

1、 Firstly, it is necessary to consider the benefits of improving the utilization rate of metal materials, reducing the variety and specifications of materials, and minimizing material loss. If possible, consider using low-cost materials to achieve zero waste during cutting.

2、 In terms of design, it should be ensured that the processed parts can be used normally, and the requirements for dimensional accuracy and surface roughness levels should be appropriately reduced to facilitate product exchange, reduce waste, and ensure stable product quality.

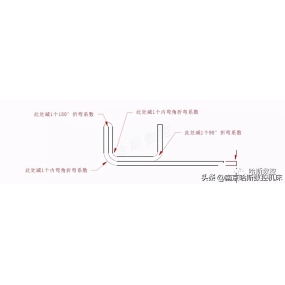

3、 The design of processed parts should be conducive to the processing of existing equipment, process equipment, and process flow, and can extend the service life of stamping dies.

In short, the design of stamping parts by stamping factories is very important. It is not only necessary to have simple shapes and reasonable structures to simplify the structure of the mold, but also to simplify the number of processes. Therefore, stamping factories need to facilitate the organization and implementation of mechanized and automated production, in order to improve labor productivity and the qualification rate of processed parts.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque