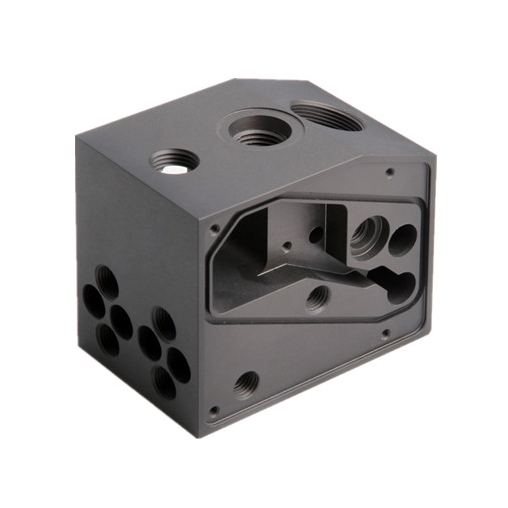

CNC five axis machining has multiple significant advantages in production, which make it irreplaceable in the field of complex parts manufacturing. The following are the main advantages of CNC five axis machining: ① Strong ability to machine complex surfaces: Five axis machining machines can move in five directions simultaneously, including three linear axes (X, Y, Z) and two rotational axes (A, B or A, C). This flexibility enables five axis machine tools to process complex surfaces and irregular parts, such as aircraft blades, molds, etc., which traditional three-axis machine tools cannot match. Improving machining accuracy: During five axis machining, the tool can always maintain the optimal angle with the workpiece surface, thereby reducing cutting force and vibration, and improving machining accuracy and surface quality. In addition, five axis machine tools are usually equipped with high-precision control systems and detection devices, which can monitor and adjust the machining process in real time to ensure machining accuracy Reduce clamping frequency: In five axis machining, the workpiece can be machined on multiple surfaces in one clamping, reducing errors caused by multiple clamping and positioning. This can not only improve production efficiency, but also reduce production costs and processing cycles Improving material utilization: Five axis machining can achieve processing of complex shapes, allowing previously difficult to process waste materials to be utilized and increasing material utilization. Meanwhile, five axis machining can also reduce the amount of waste and cutting fluid used during the machining process, and lower environmental pollution Shorten the development cycle of new products: Five axis machining has high flexibility and adaptability, which can quickly respond to market demand and product changes. In the process of new product development, five axis machining can quickly produce samples or prototypes for designers and engineers to evaluate and improve, thereby shortening the development cycle Reduce production costs: Although the initial investment in five axis machining machines is relatively high, in the long run, five axis machining can reduce production costs. On the one hand, five axis machining can improve production efficiency and material utilization; On the other hand, five axis machining can reduce errors and scrap rates caused by multiple clamping and positioning, thereby lowering production costs Strong adaptability: Five axis machining machines have strong adaptability and can process workpieces of various materials, shapes, and sizes. Whether it's metal, plastic, or composite materials, five axis machining can easily handle them. This makes five axis machining have broad application prospects in aerospace, automotive, mold, medical and other fields.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque