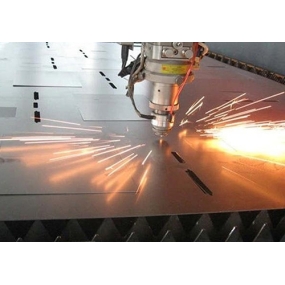

Firstly, the five axis machining solution for durable titanium alloy parts has extremely high rigidity and stability. Traditional processing methods may face the problem of insufficient rigidity during the machining process, especially when processing titanium alloy parts with messy shapes. Five axis machining, through multi axis linkage, enables cutting tools to cut around any angle, addressing the issue of insufficient rigidity. This durable processing method ensures the machining quality and accuracy of titanium alloy parts.

Secondly, the five axis machining treatment scheme for durable titanium alloy parts can help extend their lifespan. Titanium alloy materials have high hardness and wear resistance, so cutting tools are easily worn during the machining process. The use of five axis machining technology can adjust the orientation and direction of cutting tools according to the actual shape requirements of the workpiece, reduce tool wear, and extend the service life of the workpiece.

In addition, the five axis machining treatment scheme for durable titanium alloy parts can improve machining power. Under traditional machining methods, the workpiece needs to be repeatedly clamped and adjusted in orientation to complete the machining of messy shapes. However, five axis machining enables the workpiece to complete the machining of multiple angles and surfaces with one clamping, greatly improving production power.

Accuracy and surface quality are very important indicators in the five axis machining process of titanium alloy parts. Due to the special nature of titanium alloy materials, their processing requirements are very high. The five axis machining treatment scheme for durable titanium alloy parts can achieve micrometer level machining accuracy and excellent surface quality through high-precision cutting motion, stable workpiece clamping system, and excellent control system.

The five axis machining solution for durable titanium alloy parts is an innovative industrial manufacturing method that has brought breakthrough development to the processing and production of titanium alloy parts. This treatment solution has been widely applied in many industries by providing high rigidity and stability, extending the lifespan of materials, increasing production power, and ensuring processing accuracy and surface quality. With the continuous advancement of technology, the five axis machining solution for durable titanium alloy parts will continue to develop and play a greater role in promoting the innovation and development of industrial manufacturing technology.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque