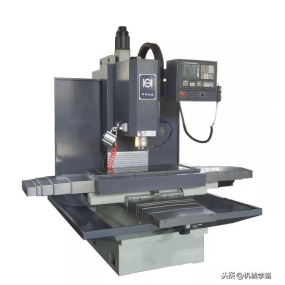

Five axis CNC Machining skill is a type of CNC machining skill that adds two rotational axes (A and B axes) to the three-axis linear motion (X, Y, Z axes).

This processing skill can complete processing in multiple directions on one workstation, and then achieve high-efficiency and high-precision processing results.

Five axis CNC machining skills are widely used in fields such as aviation, cars, molds, medical equipment, etc.

advantage

1. High efficiency: Five axis CNC machining skills can simultaneously perform machining in multiple directions on one workstation, saving machining time and improving machining efficiency.

2. High precision: Five axis CNC machining skills can complete high-precision machining of complex surfaces and meet the requirements of high-precision machining.

3. Stable accuracy: The machining accuracy of the five axis CNC machining skill is controlled by the motion track of the worktable, so the accuracy is stable and the precision and quality of the machining can be achieved.

4. Wide processing scale: Five axis CNC machining skills can process workpieces of various materials and shapes, and then meet the processing needs of different categories.

5. High degree of automation: Five axis CNC machining skills have the characteristic of high degree of automation, which can greatly reduce labor input and improve production efficiency.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque