China is the country with the most complete industrial system in the world. Since 2010, China's manufacturing value added has ranked first in the world for 13 consecutive years. In 2022, China's manufacturing value added accounted for 27.7% of GDP.

However, at the same time, China's manufacturing industry also faces many challenges. The rise in labor costs, the gradual loss of cost advantages, the gradual saturation of the domestic market, and the intensification of international trade frictions have made it urgent for China's manufacturing industry to take measures to respond, seek new development drivers, and achieve high-quality development.

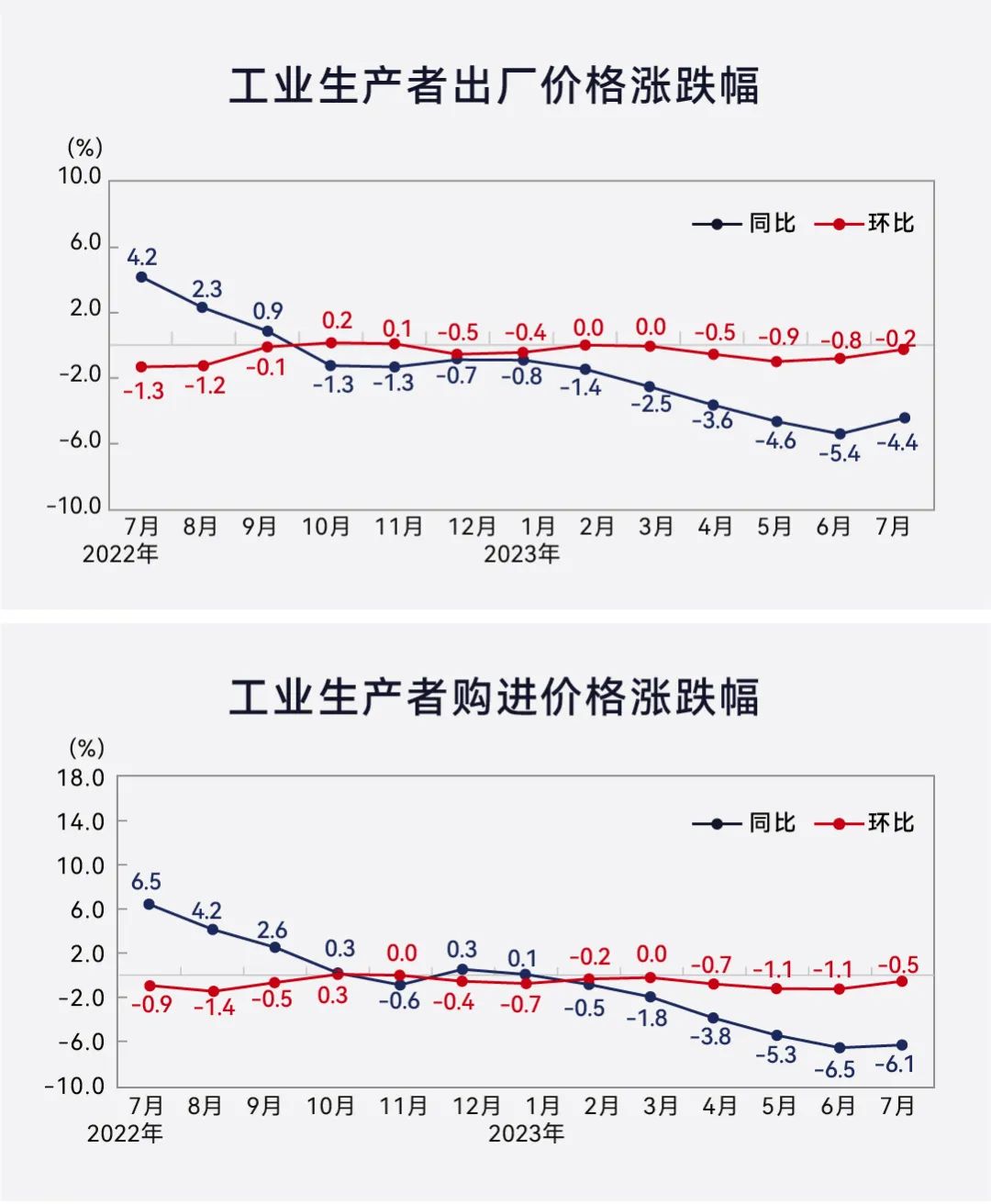

In July, the ex factory prices of industrial producers nationwide decreased by 4.4% year-on-year, a decrease of 1.0 percentage point narrower than the previous month; A month on month decrease of 0.2%. The purchasing prices of industrial producers nationwide decreased by 6.1% year-on-year, which is 0.4 percentage points narrower than the previous month; A month on month decrease of 0.5%. From January to July, the factory prices and purchase prices of industrial producers nationwide decreased by 3.2% and 3.5% year-on-year, respectively.

As the pace of economic recovery in many important countries slows down, China's manufacturing industry is not only facing intensified competition in foreign markets, but also shrinking domestic markets. In this environment of internal and external troubles, the manufacturing industry urgently needs to transform and upgrade to improve its core competitiveness. It not only needs to improve product quality and added value, but also needs to reduce production costs and improve production efficiency.

For this reason, enterprises need to introduce a series of new technologies, processes, and materials, open up new ways to reduce costs and improve quality, fundamentally reduce the consumption of raw materials, and improve product quality. And when upgrading technology, it should be fast, accurate, and stable. Try not to spend too much time and effort. On the premise of ensuring product quality, accelerate the progress of technological improvement, control costs, and strive to reap investment returns as soon as possible.

As one of the fundamental industries in the manufacturing industry, Sheet Metal Processing is also facing the upgrading of market demand and intensified competition. With the promotion of the national high-quality development strategy and the continuous upgrading of market demand, terminal products have put forward higher requirements for the accuracy, shape, and lightweighting of sheet metal parts. Processing plants and terminal enterprises are no longer facing the problem of prioritizing the purchase of higher power laser equipment to improve processing efficiency and enhance market competitiveness, but how to improve comprehensive energy efficiency through a complete system of cost reduction and efficiency enhancement solutions, deeply cultivate the needs of segmented fields, equip more stable, intelligent, and professional tools, match processing requirements, and increase investment returns.

The market industry is gradually becoming more specialized, and customized solutions for a single field or product will be more favored by users. Therefore, high-end intelligent equipment products are gradually developing towards industrialization and specialization to meet the professional needs of different users and industries.

In the sheet metal processing industry, low price competition still exists, and price wars persist for a long time, making it difficult for a large number of small and medium-sized enterprises in the industry to survive. Therefore, enterprises need to seek differentiated competitive strategies, improve their own advantages through specialized manufacturing equipment, improve processing efficiency while ensuring product quality, and reduce production costs in order to stand invincible in competition.

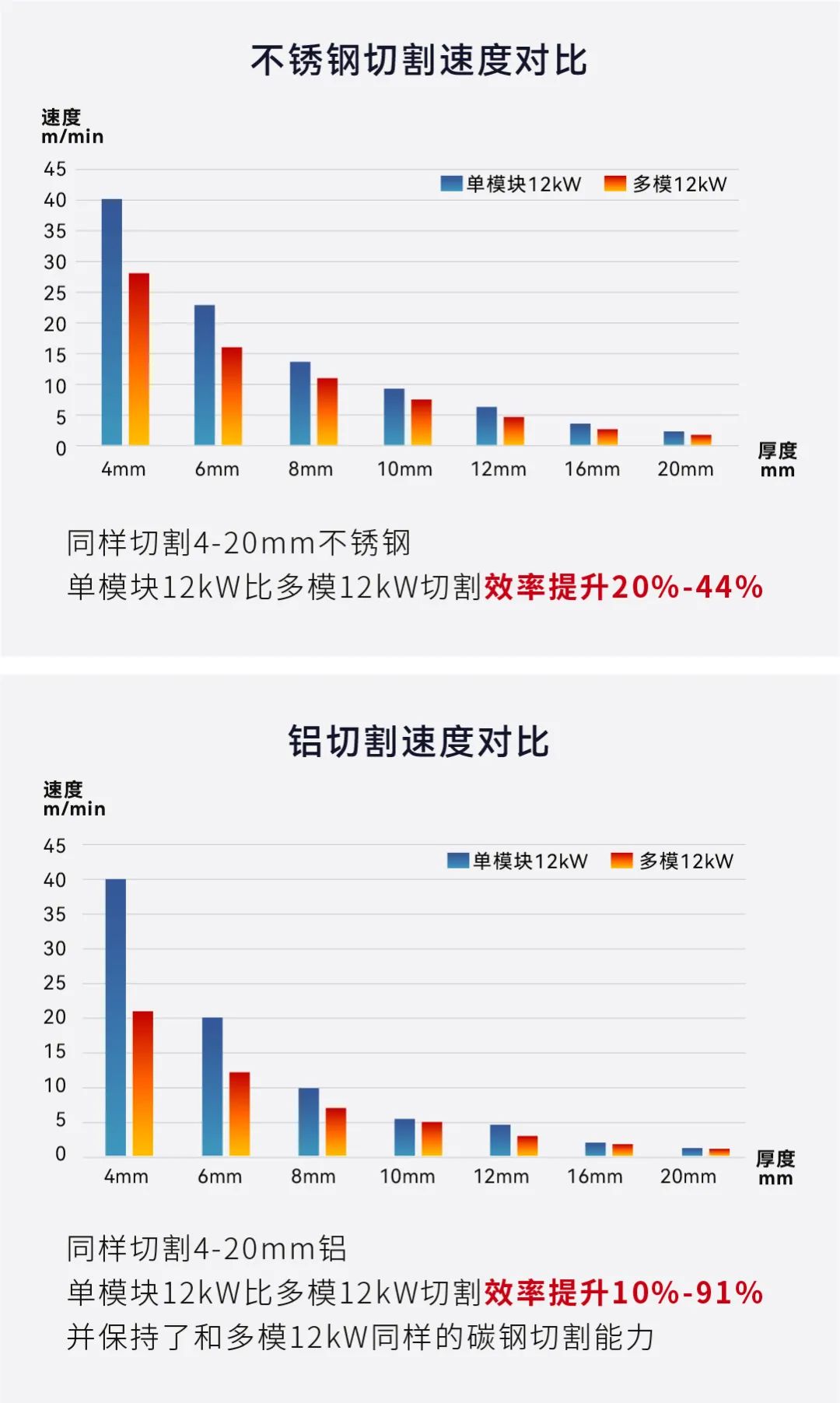

Driven by market and user demand, Chuangxin Laser innovatively launched a single module 12kW integrated 10000 watt intelligent cutting solution of "laser+cutting head+system" in 2021, fully coordinating and mobilizing the potential of the three major components of laser, cutting head, and system to operate on the same platform. Under the premise of ensuring sufficient energy density, by the specific combination of cutting head and laser, the light spot characteristics are changed, achieving the goal of improving cutting speed while ensuring cutting quality. As of now, Chuangxin Laser's "three in one" has been steadily shipping for more than 2 years and has been recognized and affirmed by a large number of end users.

The laser and laser cutting head are the two core components of a laser cutting machine. The laser is like a reservoir, and the cutting head is like a faucet, controlled by system software in the middle. The laser cutting head continuously releases high-energy laser beams, shining them on the surface of the workpiece to complete the cutting of metal sheets, pipes, and other forms of materials. The release of energy needs to be precise and appropriate to achieve the best cutting effect, which requires perfect coordination and cooperation among the laser, laser cutting head, and system software.

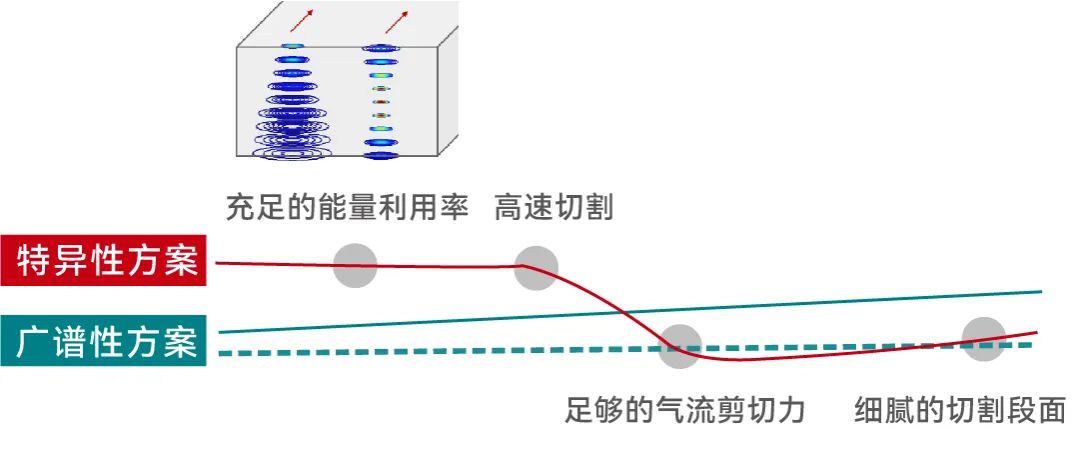

Traditional 10000 watt cutting mostly adopts broad-spectrum solutions. As the laser and cutting head are independently developed by their respective manufacturers, the cutting process can only consider two key points (as shown by the green dashed line in the figure below). Like oxygen cutting, although it ensures the cross-section and fusion edge, it cannot fully utilize laser energy and cannot break through the speed; Alternatively, only the parts of each key point can be considered, and a compromise solution can be made (such as the solid green line in the following figure).

The "three in one" integrated solution of Chuangxin Laser has created a specific solution. Through collaborative optimization of the internal technical parameters of the laser and cutting head, the laser and cutting head can simultaneously meet the requirements of four key points during operation, fully utilize laser energy, and achieve higher cutting speed of high-quality cross-sections.

At present, China is in a critical stage of transforming from a manufacturing powerhouse to a manufacturing powerhouse. As one of the basic industries in the manufacturing industry, sheet metal will gradually optimize its industrial structure under the promotion of national policies, continuously upgrading towards high-end, environmental protection, automation, and other directions. This requires synchronous upgrading support of high-end manufacturing equipment. Therefore, Chuangxin Laser is actively promoting the launch of the "three in one" enhanced version, providing stronger support for the upgrading and development of China's sheet metal processing industry.

Source: Chuangxin Laser

-------------------------------------------------------------------------------------

2024 China International Metal Forming Exhibition (7.4-7 Shanghai)

[Forging Exhibition] | Forging Equipment Technology/Auxiliary Equipment and Technology/Industrial Furnaces, Kilns and Energy saving Technology/Forging Inspection Equipment and Technology/Other

Stamping Exhibition | Stamping Deep Drawing/Hydraulic Forming/Spinning and Other Special Forming/Stamping Auxiliary Equipment and Technology

[Sheet Metal Exhibition] | Forming/Cutting of Thin Plate, Pipe, Profile and Wire/Surface Treatment of Sheet Metal/Equipment and Technology for Sheet Metal Production

【 Mold and Fixture Exhibition 】 | Forging Mold/Stamping Mold and Sheet Metal Making Mold/Mold Auxiliary Equipment and Technology

[Connection Welding Exhibition] | Arc Welding/Resistance Welding/High Energy Beam Welding Equipment and Other/Connection/Auxiliary Equipment and Tools

【 Parts Exhibition 】 | Forging/Stamping/Sheet Metal Parts/Other

【 Auxiliary Materials 】 | Welding materials/ingots, billets, and metal bars, non-ferrous metals/metal plates, pipes, profiles, wires/saw blades, saw blades, and surface cleaning materials for metal plates

[Data processing, intelligence, informatization, and automation systems/Inspection and testing of sheet metal forming parts, molds, and welding connections]

[Factory/Warehouse Equipment]

[Process Control/Quality Assurance, Safety Production and Environmental Protection]

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque