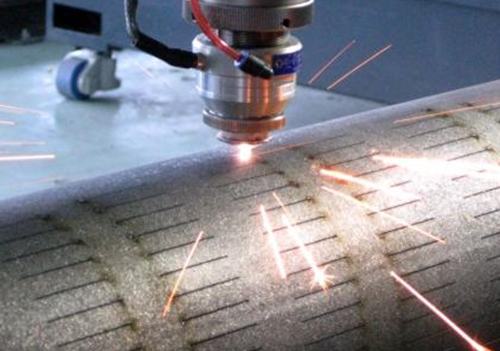

Shenyang laser cutting machine has very good cutting effect, which is superior to traditional processing and cutting due to its obvious advantages of flexible processing, time-saving, labor-saving, and high precision. Due to the increasingly widespread use of metal laser cutting machines, they are being applied in industries such as Sheet Metal Processing, aviation, electronics, electrical appliances, and kitchenware. Below, the editor will introduce how to use a laser cutting machine to achieve good cutting results.

1. The cooling system needs to be grounded, and the water tank and waterway should be cleaned regularly. The temperature control point of the refrigeration temperature control water tank should be fair, otherwise it will cause easy damage to the laser tube, decrease in condensation power, detachment of the cold water head of the tube, greatly shorten the service life, and sometimes fail to work, resulting in continuous tube replacement.

2. The installation support point of the laser tube of the laser cutting machine should be reasonable, and the support point should be at 1/4 of the total length of the laser tube, otherwise it will cause the laser tube spot mode to deteriorate, and some work for a period of time will cause the spot to become several points, resulting in a decrease in laser power that cannot meet the requirements, causing continuous tube replacement.

3. Water protection should be checked and cleaned regularly. Cooling water often cannot flush the water protection float switch or the water protection float switch does not reset. Short circuiting methods should not be used to solve urgent problems.

4. The suction device should be checked and cleaned regularly, and the fan ducts should be cleaned thoroughly Otherwise, a lot of smoke and dust cannot be discharged, severely and quickly polluting the lenses and laser tubes, causing easy oxidation of various mechanical and electronic components and poor contact.

5. Focus lens and reflector inspection, after working for a while, the frame will have a fever, and the surface of the lens will change color and rust; Peeling and cracking are all objects that need to be replaced, especially for many customers who use large air pumps and compressors, which quickly accumulate water on the focusing lens. Therefore, it is necessary to check the cleanliness and quality of the lens optical path system on time.

6. The working environment of the laser cutting machine should not be too harsh. If the ambient temperature is above 30 degrees and below 18 degrees, there will be too much dust and severe air pollution, which will severely damage the machine and increase the failure rate; Electrical components are prone to problems in humid environments.

For many years, as a professional laser cutting machine, fiber laser cutting machine, laser engraving machine, laser marking machine, laser welding machine, laser cleaning machine, large format laser cutting machine and other equipment

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole