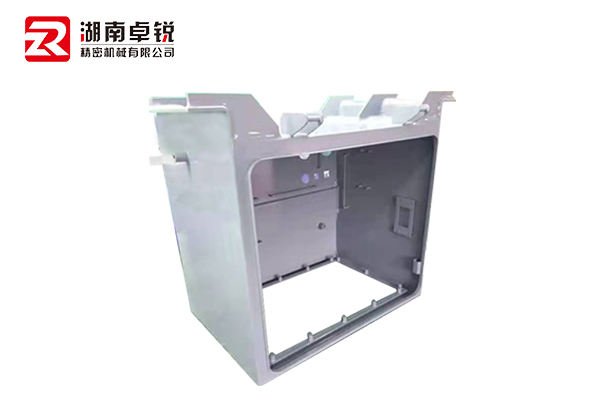

Precision Sheet Metal Processing is a professional processing technology mainly used for manufacturing high-precision metal products. The processing flow generally includes the following steps:

1. Design and Drawing: Before starting processing, design and drawing are necessary first. Develop a product design plan based on customer needs and requirements, and draw detailed manufacturing drawings according to the design plan.

2. Material preparation: Before processing, it is necessary to prepare the required sheet metal materials. According to the requirements of the design drawings, select appropriate materials and cut and organize them for subsequent processing and use.

3. Cutting and Forming: Place the prepared sheet metal material into a CNC cutting machine or CNC bending machine for cutting and forming. According to the requirements of the design drawings, accurately cut and bend to ensure the accuracy and quality of the product.

4. Welding and assembly: Welding and assembling parts that have been cut and formed. Use welding equipment to weld sheet metal parts together and perform necessary assembly work to complete the manufacturing of the product.

5. Surface treatment: Surface treatment of processed products, such as spraying, sandblasting, chrome plating, etc. Surface treatment can improve the appearance quality and durability of products.

6. Quality inspection: Conduct quality inspection after processing is completed. By inspecting the dimensions, appearance, structure, and other aspects of the product, ensure that it meets the design requirements and has good quality.

7. Packaging and Transportation: Packaging and arranging transportation for products that have passed quality inspection. Ensure that the product is not damaged during transportation and remains intact when it reaches the customer's hands.

The above is the main process of precision sheet metal processing, and each step requires careful operation and strict control to ensure the quality and accuracy of the product. Precision sheet metal processing technology has a wide range of applications in fields such as automotive, aerospace, and electronics, and is of great significance for improving product quality and performance.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque