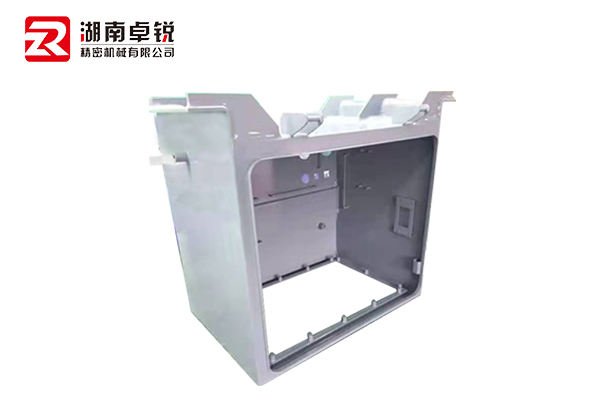

Precision Sheet Metal Processing is a technology used to produce precision parts and components, which typically requires a combination of various professional techniques and processes to complete. Here are some commonly used professional techniques in sheet metal processing manufacturers:

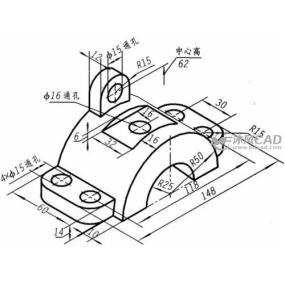

1. Sheet metal processing technology: Sheet metal processing is a method of forming various complex shapes by bending, cutting, stretching and other processing techniques on metal sheets. In precision sheet metal processing, sheet metal processing technology is essential.

2. Cutting technology: Cutting technology is a method of accurately cutting metal sheets according to design requirements, usually including laser cutting, plasma cutting, stamping cutting and other technologies.

3. Bending technology: Bending technology is the process of bending metal sheets into the desired shape through mechanical force or thermal processing, typically including techniques such as bending and shaping.

4. Welding technology: Welding technology is the technique of connecting multiple metal components through thermal processing methods, including welding, spot welding, argon arc welding, and other technologies.

5. Surface treatment technology: Surface treatment technology is the process of surface treating metal components through chemical treatment, spraying, and other methods to improve their corrosion resistance, appearance, and other characteristics.

6. CAD/CAM technology: CAD/CAM technology is a method of machining design and control through computer-aided design and manufacturing technology, which can improve the accuracy and efficiency of precision sheet metal machining.

7. Quality control technology: Quality control technology is a method of monitoring and managing the quality of processing and finished products through strict process control, testing, and inspection methods to ensure that products meet design requirements.

In actual precision sheet metal processing, it is usually necessary to combine the above multiple technologies to complete the production process. Only by mastering these professional skills can we ensure the quality and accuracy of precision sheet metal processing products.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole