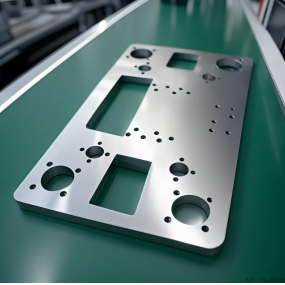

A fixture is a specialized fixture used to hold and position workpieces or cutting tools in process machining, ensuring the machining accuracy and quality of the workpiece. The main function of fixtures is to fix workpieces or tools and maintain their accuracy, stability, and directionality during the machining process. Therefore, the design, manufacturing, and use of fixtures have a significant impact on machining quality, efficiency, and cost.

1、 Classification of fixtures and jigs

There are many types of fixtures and jigs, which can be mainly divided into three categories: positioning fixtures, clamping fixtures, and combination fixtures.

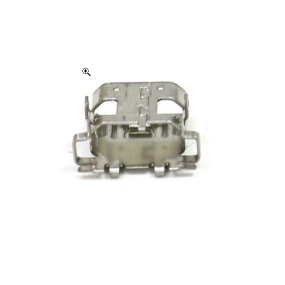

1. Positioning fixture: mainly used to locate and fix the position of the workpiece. Positioning fixtures include center positioning fixtures, panel fixtures, template fixtures, slider fixtures, etc.

2. Compression fixture: mainly used to clamp and fix workpieces and cutting tools. Compression fixtures usually include chucks, elastic fixtures, oil cylinder fixtures, pneumatic fixtures, etc.

3. Combination fixture: Combine the positioning fixture with the clamping fixture to achieve better clamping effect. Combination fixtures usually include quick change fixtures, automatic switching fixtures, combination spiral fixtures, etc.

2、 Design principles of fixtures and jigs

When designing fixtures and jigs, the following principles should be noted:

1. The clamping force should fully meet the processing requirements and ensure that there is no slippage between the fixture and the workpiece.

2. The rigidity of the fixture should be sufficient to withstand the effects of cutting and impact forces.

3. The fixture should have the characteristics of easy operation, high precision, and high production efficiency.

4. The design of fixtures should coordinate the processing technology and machine conditions to ensure the stability of the processing technology and production efficiency.

3、 Manufacturing process of fixtures and jigs

The manufacturing process of fixtures mainly includes the following steps:

1. Fixture design: Design a reasonable fixture structure based on the shape, structure, and processing requirements of the workpiece, and select appropriate materials and standard parts.

2. Processing of fixtures and jigs: including the processing of fixture positioning holes, clamping holes, threaded holes, etc., as well as the assembly and debugging of fixtures and jigs.

3. Surface treatment of fixtures: including rust prevention treatment, painting and other surface treatments.

4. Fixture inspection: Conduct quality inspections on the size, shape, and position of the fixture to ensure that it meets the processing requirements.

4、 Use and maintenance of fixtures and jigs

1. Before use, carefully check whether the clamping force of the fixture meets the processing requirements, and make necessary calibration and adjustment.

During use, the fixture should be inspected and maintained in a timely manner, such as keeping the fixture clean, maintaining lubrication, and preventing damage.

During the processing, it is necessary to avoid exceeding the rated load range of the fixture, and to avoid accidental operations such as collisions and impacts.

After the processing is completed, the fixture should be disassembled, cleaned, and maintained in a timely manner to ensure the long-term service life of the fixture.

5、 Conclusion

Fixtures are indispensable and important tools in modern industrial production, which can greatly improve processing quality and efficiency. The design, manufacturing, and use of fixtures and jigs should follow relevant specifications and standards to achieve the best results. At the same time, it is necessary to maintain the good condition of the fixtures and implement effective maintenance and management in order to maximize their advantages.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque