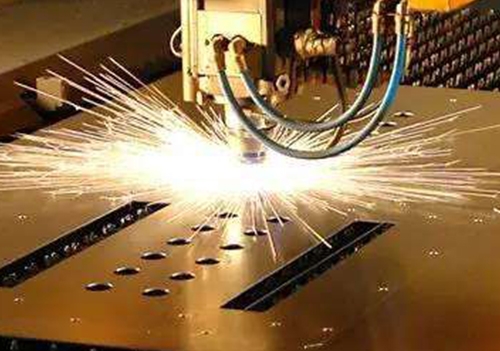

What are the reasons for low production efficiency in laser cutting?

One of the reasons why laser cutting is widely praised in the metal processing industry is its high production efficiency and low processing cost, which has significant advantages compared to other cutting methods. However, many customers have found that their production efficiency has not improved significantly after using it for a period of time. What is the reason for this? Below we will explain the reasons for the low production efficiency of laser cutting.

1. No automatic cutting process

Laser cutting does not have an automatic cutting process and cutting parameter database on the system. Cutting operators can only manually draw and cut based on their experience, and automatic perforation and cutting cannot be achieved during cutting, requiring manual adjustment. Over time, the efficiency of laser cutting will naturally be very low.

2. Inappropriate cutting method used

When cutting metal sheets, common edge, borrowed edge, bridging and other cutting methods were not used. In this way, the cutting path is long and the cutting time is long, resulting in low production efficiency. At the same time, the amount of consumables used will also increase, leading to high cost expenditures.

3. Not using nesting software

The nesting software was not used for typesetting and cutting, but manual typesetting was performed in the system, cutting the parts in the order they were cut. This will result in a large amount of scraps being generated after cutting the board, low utilization rate of the board, and the cutting path not being optimized, leading to long cutting time and low production efficiency.

4. The cutting power does not match the actual cutting thickness

Not selecting the corresponding laser cutting according to the actual cutting situation. For example, if a large quantity of 16mm carbon steel plate needs to be cut in practice, and a 3000W power cutting equipment is selected, the equipment can indeed cut 16mm carbon steel plate, but the cutting speed is only 0.7m/min, and long-term cutting will increase the damage rate of lens consumables, and even affect the focusing lens. It is recommended to use 6000W power for cutting and processing.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque