Regarding the cutting of Metal Stamping parts, based on EMAR Precision's years of stamping experience, the size and shape of the cutting process for metal stamping parts should depend on the local conditions and the requirements of its external supplementary materials. Generally, the following principles need to be followed:

1. The incision of metal stamping parts should adapt to the shape and contour of local protrusions, so that the material can flow reasonably;

2. There should be sufficient overlap between the incisions to allow the punch to tighten the material, ensure clear forming, avoid defects such as ripples, and ensure good quality of the flanged holes after trimming;

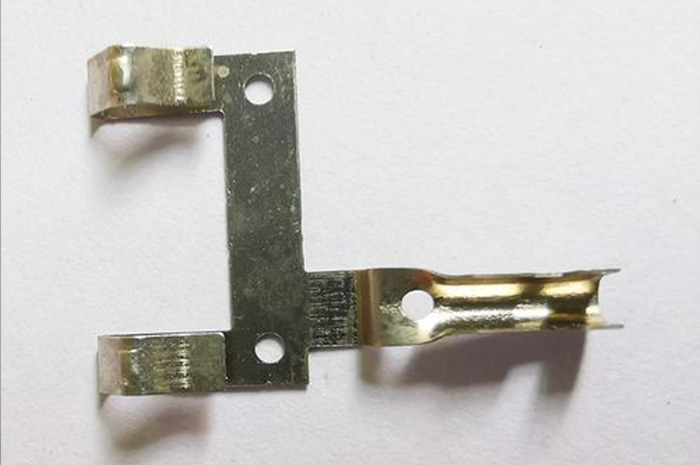

Metal stamping parts

3. The separation position of the incision, that is, the opening position, should be close to the edge of the protruding part of the metal stamping part or the area prone to cracking;

4. The number of cuts in metal stamping parts should ensure that the material at the protrusions can deform evenly, otherwise it may not be possible to prevent the occurrence of ripples;

The above principles of cutting layout for metal stamping parts are shared with everyone, hoping to help everyone. EMAR Precision is a manufacturer specializing in manufacturing various precision metal stamping parts, with a complete quality management system and a leading enterprise in the industry. We strive to create the most perfect service experience for our customers. Welcome to cooperate with us for information.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque