Precision Sheet Metal Processing is a high-precision and high-efficiency processing method widely used in industries such as electronics, communications, automotive, and medical. In order to ensure product quality and production efficiency, precision sheet metal processing must follow a series of processing specifications. The following are the processing specifications for precision sheet metal processing:

1. Design specifications: Before precision sheet metal processing, it is necessary to design a suitable processing plan and process flow according to product requirements. When designing, the functional requirements, structural features, and material properties of the product should be considered to ensure machining accuracy and surface smoothness.

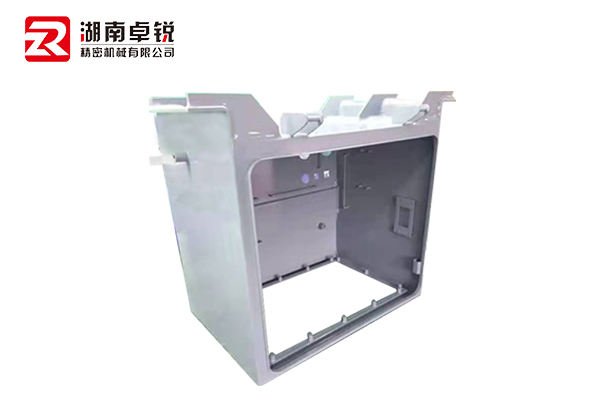

2. Material selection: In precision sheet metal processing, the choice of material directly affects product quality and processing efficiency. Suitable materials such as stainless steel, aluminum alloy, etc. should be selected according to the usage environment and requirements of the product to ensure its corrosion resistance and mechanical properties.

3. Process specifications: When carrying out precision sheet metal processing, it is necessary to strictly comply with the processing process requirements, including the process parameters and operating specifications of various links such as cutting, bending, stamping, welding, etc. To ensure stable, efficient, and precise processing.

4. Processing equipment: Precision sheet metal processing requires the use of various precision processing equipment, such as CNC punching machines, CNC cutting machines, CNC bending machines, etc. To ensure the accuracy and stability of the equipment, timely maintenance and upkeep of the equipment are necessary to ensure processing quality and efficiency.

5. Testing and quality control: In the process of precision sheet metal processing, regular testing and quality control should be carried out to promptly detect and correct problems. To establish a sound quality management system, inspect the processing and finished products to ensure that the products meet the requirements.

6. Safety regulations: Precision sheet metal processing is a high-risk processing process, and operators must strictly comply with safety regulations, wear relevant protective equipment, and ensure personal safety. At the same time, it is necessary to prevent mechanical and chemical accidents and ensure the safety of the production environment.

In summary, the processing specifications for precision sheet metal processing cover multiple aspects such as design specifications, material selection, process specifications, processing equipment, testing and quality control, and safety specifications. Following these specifications can ensure the quality and efficiency of precision sheet metal processing, and improve product competitiveness.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque