Sheet Metal Processing plays an important role in modern industrial manufacturing, and sheet metal chassis, as a common product, require precise and meticulous operation in its processing technology. Below, the sheet metal processing manufacturer will provide a detailed introduction to the sheet metal chassis processing technology.

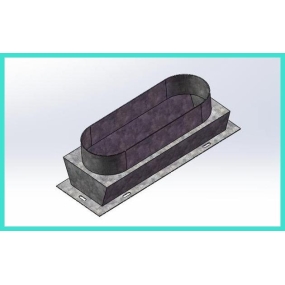

Firstly, before processing the sheet metal chassis, the designer needs to conduct a preliminary design based on the requirements and design drawings provided by the customer. The designer will determine the size, shape, structure, etc. of the chassis and draw it through software. This design stage is crucial, as the rationality of the design directly affects the smooth progress of subsequent processing.

Next is the material preparation stage. Choosing the appropriate sheet metal material is an important factor in ensuring the quality of the chassis. The commonly selected sheet metal materials include cold-rolled sheet, hot-rolled sheet, galvanized sheet, etc. According to the design requirements, it needs to be cut into corresponding sizes.

The next step is the punching process for sheet metal chassis. Use a punch press to cut sheet metal materials into the desired shape and size, such as the bottom and side panels of a chassis. In the punching process, it is necessary to consider the thickness and strength of the material to avoid errors and waste.

Next is the bending process. The punched sheet metal parts are bent by a bending machine to form the main structure of the chassis. The bending process requires precise control of angle and length to ensure the stability of the chassis structure.

Next is the welding process. Weld the bent sheet metal parts together to form a complete chassis structure. The welding process requires skilled workers to operate, master the welding temperature and time, and ensure that the welding points are firm.

Z is followed by surface treatment process. After welding, there may be some defects on the surface of the chassis, and surface treatment processes such as polishing and painting are needed to make the appearance of the chassis more beautiful.

Through the above process flow, the processing technology of sheet metal chassis is completed. This process requires professional skills and experience, and only by strictly controlling and operating each step can the quality and accuracy of the product be guaranteed. I hope my introduction can help you better understand the process of sheet metal chassis processing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque