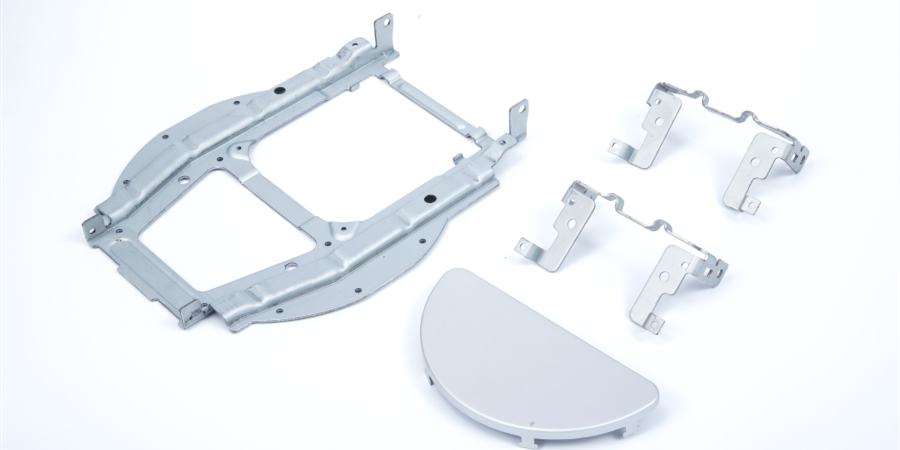

Deep drawing stamping parts are stamped parts that deform sheet metal materials into cylindrical or box shapes using stamping, pull rings, or metal molds. Due to the need to deform metal, Metal Stamping factories often use hot forming for the production of deep drawn parts. This involves heating the billet until it softens, placing it in a mold for molding, and setting a cooling structure inside the mold to ensure that it is at a lower temperature. This allows the billet to cool in a timely manner to ensure that the shape of the deep drawn part can be fixed.

This stamping method has become increasingly widely used in many fields, and its working principle is very similar to that of general stamping processing. However, the deep drawing stamping process is more excellent than the general stamping process and has four major advantages:

1. High end quality

The product quality of deep drawn stamping parts is well known in most hardware stamping factories, because there is mold production and assistance during processing, so the processed products are very precise in shape and size. Moreover, in the production process of molds, their service life is also very long, so the quality of deep drawn stamping parts produced in the market is high-end.  2. Scope of application

2. Scope of application

The scale of each deep drawn stamping part is different, and the produced parts have very precise scales. It can be used in our daily life and industrial production, such as household electronic devices, car manufacturing, and the watches we wear. Therefore, this type of equipment is used in many places.

3. Simple and efficient

In terms of overall process control, each step in the production of deep drawing stamping parts is controlled like a production line, so the complexity of personnel operation is much simpler than that of general stamping methods. The maintenance of equipment has become increasingly comfortable, and the performance of deep drawn stamping parts has been better improved, especially in terms of sealing and internal strength.

4. Energy conservation and environmental protection

Energy conservation and environmental protection are the advantages of deep drawing stamping parts, mainly due to their special manufacturing process. During the processing, many materials are used reasonably and do not require too much energy consumption. This not only saves energy but also reduces production costs. Therefore, it can improve the efficiency of many hardware stamping factories and pursue energy conservation and environmental protection in modern society.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque