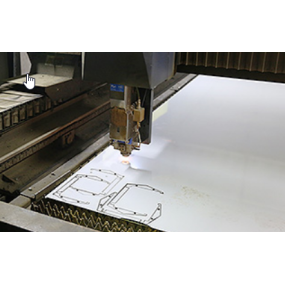

1. Choose a reasonable cutting amount. The staff selects the cutting speed to be used based on the material, hardness, cutting state, material type, and cutting depth of the aluminum shell to be processed. These conditions are essential for effectively reducing machine wear and tear.

2. Choose the appropriate cutting tools. Generally speaking, when rough cutting, it is better to choose tools with high strength and durability, which can better meet the requirements of rough cutting.

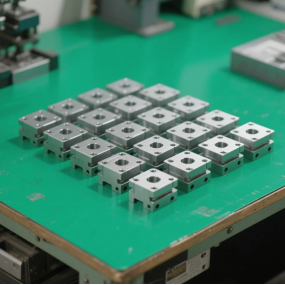

3. Select appropriate fixtures. The parts should fully meet the needs of the machine to reduce unnecessary positioning errors and select specialized fixtures and clamping tools.

4. Determine a reasonable processing route. Try to shorten the machining path of the aluminum shell during CNC Machining and reduce machine wear as much as possible.

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque