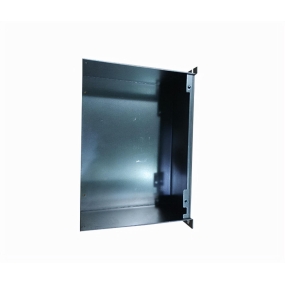

We can design the overall framework scheme according to the requirements for framework processing. The confirmed plan also requires the issuance of processing and installation drawings. In addition to the common black and white colors, excellent chassis also incorporates various appearance features into the panel design, which is elegant, generous, stable and lively. Paired with white, it is both eye-catching and practical. The mechanical processing workshop not only needs to meet the technical requirements of customer workpiece processing, but also has the required performance. At the same time, we should pay attention to improving production efficiency and workers' work efficiency, and provide customers with more economical, long-term and effective services. The processing technology of frame welding can be divided into rough machining, corner cleaning, and precision machining. When rough machining, larger cutting tools should be used and a large workpiece allowance should be quickly cut on the machine tool to achieve rough machining of fine parts. The principle of tool selection mainly depends on whether the chamfered arc surface of the product is too small. After selecting the tool, determine its length.

Rack processing

In principle, the length of the cutting tool should be greater than the machining depth. Because the program steps of CNC precision machining, such as the selection of benchmarks, the selection of machining tools, the selection and installation of fixtures, the determination of machining strategies and process parameters, all affect the quality of the product. The processing method of frame welding first depends on the technical requirements of the surface of the processed part. It should be noted that these technical requirements are not necessarily the requirements on the drawings. Sometimes, due to process reasons, they may be higher than the requirements on the process drawings in certain aspects, such as using misalignment as a reference and improving machining accuracy. Metal to the surface of the component. Requirement, based on higher precision machining requirements.

Rack processing can be customized according to requirements

We can design the overall framework scheme according to the requirements. The confirmed plan also requires the issuance of processing and installation drawings. Aluminum frame processing: This frame is mainly used for delivering industrial aluminum profiles 3030R and 3030 series profiles. The sheet metal is 1.5mm electrostatic paint, and various electronic devices, automotive yellow cars, and other non-standard customized manufacturing, Some aluminum profiles require drilling and the use of semi-automatic milling machines; Milling machines are not only capable of drilling and milling surfaces, but also require high-precision CNC milling machines for milling grooves, chamfering, flying surfaces, and drilling. With the widespread use of aluminum processing, these three basic equipment for completing aluminum processing may encounter certain processes.

Rack processing

During the welding process of the frame, the surface of the weld seam shall not have defects such as virtual welding, porosity, slag inclusion, cracks, weld beads, burn through, arc craters, undercutting, welding wear, incomplete welding, etc, Uniform and aesthetically pleasing welding; The frame welding process is completed. After cleaning, the slag on the surface of the weld bead should be removed, and the size and appearance quality of the weld should be checked. Uneven welds should be repaired. The appearance of the weld seam should be smooth and uniform, and the transition between the weld bead and the base metal should be smooth. The welding parts of large frame processing should be affected by wind, rain, snow, cold, etc. The steel structure groove should be processed according to the processing drawings. Large scale automatic welding is the process of achieving atomic bonding of the material of the workpiece through heating, pressure, or a combination of both, with or without filler materials. Performing corresponding heat treatment processes on workpieces is beneficial for improving their hardness, wear resistance, and strength, greatly enhancing their accuracy and service life.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque