Do you know the process flow of rack processing?

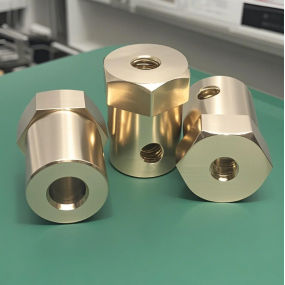

The process flow of rack machining refers to the steps of manufacturing and processing workpieces or parts. During the operation, mechanical processing methods can be used to directly change the shape, size, and surface quality of the blank, making it a machining process for the part. Regarding the processing procedure. For example, the machining of ordinary parts involves rough machining, precision machining, assembly, inspection, and packaging, which is a general machining process. Large scale automatic welding is the process of achieving atomic bonding of the material of the workpiece through heating, pressure, or a combination of both, with or without filler materials. Performing corresponding heat treatment processes on workpieces is beneficial for improving their hardness, wear resistance, and strength, greatly enhancing their accuracy and service life.

The main content of frame welding processing is to change the shape, size, relative position, and properties of the production management objects of the enterprise, so that they can become finished or semi-finished products. It is a detailed description of each step and process. For example, the rough machining mentioned above may include blank manufacturing, grinding, etc. Precision machining may be divided into lathes, fitters, milling machines, etc. Each step requires detailed data, such as how much roughness should be achieved and how much tolerance should be achieved.

In the welding process of large shelves, the technical personnel will determine the adopted process flow based on the quantity of products, equipment conditions, and the quality of workers, and write the relevant content into the process documents, called process regulations, which are more targeted. Each factory may be different because the actual situation varies.

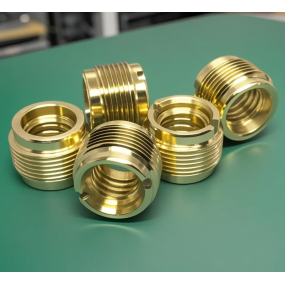

Rack processing

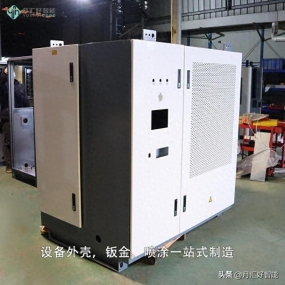

Sheet metal parts are thin metal components that can be processed externally through CNC punching, bending, stretching, and other processes. It can generally be defined as a part with constant thickness during the manufacturing process. Therefore, castings, forgings, mechanical parts, etc. The process of Sheet Metal Processing is called sheet metal processing. For example, using some boards to make a chimney, iron drum, oil tank and oil tank, ventilation pipe, elbow and head, circular area, funnel, etc. The main processes include cutting, bending, bending, bending, welding, riveting, etc. Some geometric knowledge. Sheet metal parts are thin metal parts that can be processed simultaneously through stamping, bending, stretching, and other methods. Machine frame processing of workpieces, for example, the outer iron shell of a car is a sheet metal part, and some stainless steel kitchen utensils are also sheet metal parts. The frame processing factory believes that sheet metal processing is usually the three important steps of Dongguan sheet metal processing, namely cutting, punching/cutting, and folding. The characteristics of excellent Dongguan sheet metal processing: 1. The flatness of inferior sheet metal parts needs to be greatly adjusted; 2. The gap between the original sheet metal parts and the original vehicle is only 0.3mm; 3. 4. Holes in inferior sheet metal parts. Excellent sheet metal parts require mechanized production, with smooth welding points and no burrs on the edges; 5. Excellent sheet metal parts require a high level of attention to the baking paint process, requiring uniform weight, strong adhesion, and good waterproof and antioxidant properties.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque