Nowadays, more and more batteries have increased their explosion-proof performance. A good new energy battery explosion-proof sheet must have strict technical requirements and first meet environmental protection requirements. After all, with the increase of energy saving and functionality, batteries are also hazardous materials for consumption, so environmental protection requirements are very important. The appearance of explosion-proof plates for new energy batteries should also be maintained in good condition, without looseness, burrs, or sharp edges, and without surface defects such as stains and scratches.

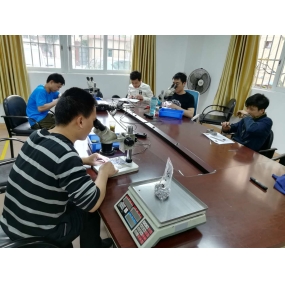

Explosion proof sheet for new energy batteries

In product use, aluminum alloy materials are mostly chosen for the processing of explosion-proof plates and power battery structures. Because aluminum alloy has certain good formability, it not only has the advantages of good surface and plasticity, but also resistance to pressure. By using aluminum alloy as the casing of the power battery in this way, it has impact resistance, is not easily broken, and does not leak out, fully meeting the strength and rigidity requirements of the power battery casing.

So a good explosion-proof sheet for new energy batteries has good processing characteristics, high corrosion resistance, and good weldability and conductivity. In addition, a good explosion-proof sheet for new energy batteries also requires a flat surface, good plasticity, high safety factor, and particularly strong explosion-proof ability. Combined with the low density and light weight of aluminum, if used in a car, the overall weight of the vehicle can also be reduced, improving the vehicle's endurance performance.

Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole