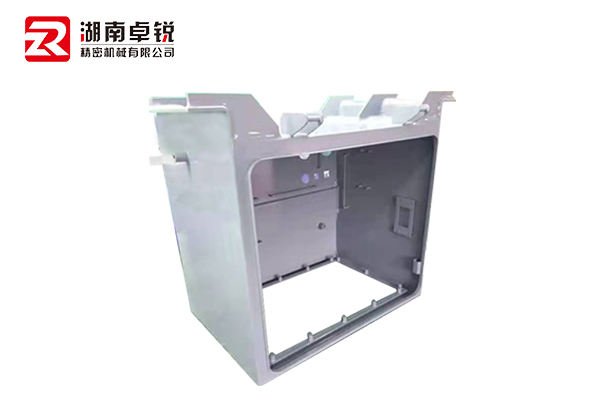

What are the requirements for surface treatment of chassis and cabinet Sheet Metal Processing? The sheet metal processing manufacturer's editor will answer below.

The requirements for surface treatment of chassis and cabinet sheet metal processing mainly include appearance quality inspection standards, precautions during the processing, and aspects that need to be noted in surface treatment.

1. Appearance quality inspection standards:

1) The requirements for machining form and position neatness include requirements for flatness, perpendicularity, and contour.

2) The surface treatment specifications involve requirements for color, uniformity, and texture, aiming to achieve horizontal and vertical alignment, uniform gaps, smooth lines, distinct contours, and uniform color effects.

2. Precautions during the processing:

1) Strictly follow the requirements of sheet metal chassis processing drawings and dimensional data, pay attention to the selection of cutting tools and slots, as well as the processing sequence (from inside to outside, from small to large, from complex to simple).

2) When processing to a certain extent, assembly and inspection are carried out to ensure that equipment data is consistent with customer data and reduce errors.

3) Choose appropriate surface treatment methods based on different materials, such as wire drawing treatment for stainless steel plates, oxidation treatment for aluminum plates, phosphating treatment after electroplating for cold plates, and surface cleaning and degreasing for electroplated plates.

3. Aspects to be noted in surface processing treatment:

1) Aluminum alloy castings should not be subjected to sulfuric acid anodizing.

2) Electroplated (oxidized) parts with riveting requirements need to be electroplated (or oxidized) first before riveting.

3) The galvanized layer should avoid contact with organic materials to prevent corrosion.

4) All electrochemical treatments should be carried out under the condition of the component to prevent chemical solutions from remaining in the gaps of the component and causing corrosion.

5) The inner surface of parts with deep grooves or fine pores may not be fully covered, so attention should be paid.

In summary, the requirements for surface treatment of chassis and cabinet sheet metal processing cover multiple aspects from processing shape and position neatness to surface treatment specifications, aiming to ensure product quality, aesthetic appearance, functionality, and durability.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque